How to Prevent Rust Treatment of aluminium forming machine

The gear oil used in the machine tool of the aluminum profile cold-bending machine must be introduced into the automobile fuel tank after severe stress. The automobile fuel tank of the cold-bending forming machine must be cleaned before loading. The cold-bending forming machine is generally recommended for application No. 31. No. 46 hydraulic oil machine equipment is used for oil, cold bending machine must do a good job of oil and cleaning and maintenance work of this machine, cold bending machine to prevent fouling or oil leakage hazard application actual effect.

The lubricating oil of the compressor must be kept clean and tidy. The initial application time of the cold-bending forming machine should not exceed two months. When the cold-bending forming machine is replaced, the cold-bending forming machine should clean the filter and the automobile fuel tank together, and the cold-bending forming machine pays attention to the filter. It can be put into gasoline for cleaning. The cold-bending forming machine can not be cleaned with a hard and soft brush. The cold-bending forming machine such as the compressor lubricating oil is not mildewed, and the cold-bending forming machine can still be applied after careful consideration.

It is often checked whether the machine equipment needs to be wet or not. After the completion of a class work, use the hydraulic cylinder for the cold bend forming machine. If the machine equipment is not used for a long time, the cold bend forming machine should be coated with anti-rust agent on the surface of the dragging.

Rolling Shutter Slats Roll Forming Machine's Characteristics and Operating Procedures:

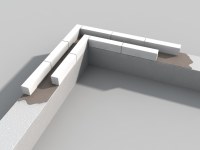

1. 8mf aluminum profile cold bending forming machine is the product of our factory to develop new automatic bending channel steel products. The hydraulic transmission system is selected, which has the characteristics of stable transmission system and too much pressure. The round steel steel can be formed multiple times, and the design scheme of the improved automobile chassis is selected to ensure that the application is not deformed;

2. Drive wheel management center distance can be adjusted. Each is 2.2 meters and 1.45 meters. When bending a small half (production processing 12-18), the active wheel is installed in the 1.45 m management center.

It is convenient to replace the spare parts, no need to carry out the effect again, the customer only needs to tighten the screw to the assembly line and can only use it again.

BOSJ established in 2004, As a leading producer of many types of roll forming machines in China, BOSJ has won a worldwide reputation in this field. Our china roll forming machine have broad markets in Southeast Asia, India, North and South America, Western Asia, Russia, and Australia.

Ubicación : NO.9 XIANGDUN ROAD,HUASHI TOWN,JIANGYIN CITY,JIANGSU PROVINCE, 214400 jiangyin,

Persona a contactar : Wang Joyce , 0510 86062268