Project name:Yacht model

Material: ABS engineering plastics

Process: CNC machining

Post treatment: Painting, plating

Qty: 1 set

Advantages: high precision, fast speed and high processing efficiency

Production cycle: 15 days

Project requirements:

1. Precise proportion: The yacht model is made in 1: 40 scale

2, perfect assembly, fine surface treatment, smooth lines of finished products and even colors

Project Background

The birth of a yacht begins with a drawing. After a rigorous review, the model of the yacht is produced. This is the conceptual model of the yacht. The customer can easily make the appearance review by making the yacht model.

Project pre-stage analysis:

After receiving the design drawings sent by the customer, the production department holds a preliminary analysis meeting, and through the cooperation of various departments, detailed analysis of each problem that the product needs to pay attention to.

Process and material selection:

The hull and superstructure are mostly made of ABS engineering plastics as raw materials, and some small parts are made of metal stainless steel. Most of the manufacturing processes are done by CNC abs plastic machining . After processing, the model needs to be post-treated by grinding, painting, electroplating, etc. to enhance the appearance of the model.

Production process:

1. Disassemble and check the overall matching degree of the components: Combine with the ABS CNC machining process, split the model to ensure that the components of each level can be processed; with the help of the software, the pre-analyst optimizes the assembly of the drawings and verifies the feasibility of the drawings. .

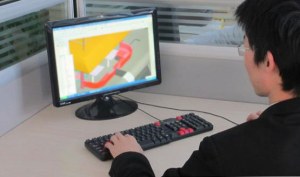

2. Programming on the machine: After preliminary analysis, programmed on the machine. In order to ensure that all parts can be finely processed, we carry out precision machining through the industry-leading CNC processing equipment to ensure the high precision of the product.

3. After the machining is completed, the rough assembly is carried out: After the CNC abs precision machining is completed, the parts are rough-assembled and necessaryly polished to ensure that the products are assembled correctly before painting.

4. Fine post-processing: according to the customer's specified requirements, the finished parts are polished, painted, electroplated and other post-treatment processes.

5. Strict quality inspection: Each component is inspected by the project manager and transferred to the quality inspection department who checks again to ensure that the product has no any quality problems.

6. Beautiful finished products

Duch Group can provide customers with rapid prototyping china, CNC processing, 3D printing, product appearance processing (grinding, polishing, vacuun casting, spraying, silk screen, pad printing, electroplating, laser engraving, wire drawing, etc.) small batch personalized product customization, mass production and other services, which can help customers quickly verify the appearance of the product, help customers achieve high-quality sample manufacturing and china prototype manufacturing. If you have the above needs, please contact us!

Ubicación : #899 Ma Qing Road, Hai Cang District, Xiamen, Fujian Province, China., 361026 xiamen,

Persona a contactar : zhang James, 86 18659258188