Product Description

Production description of High efficiency fully automatic waste tire pyrolysis plant

For High efficiency fully automatic waste tire pyrolysis plant main raw material is waste tire/tyre, which can be easily available in and part of the world. The raw material is cheaper and can use waste tire, and we get fuel oil, carbon black, steel wire as the end product. waste tyre continuous pyrolysis plant is feasible in technology with small amount of invement, high availability of materials, short recovery period and with bright future, is the ideal choice of investment.

Main feature of High efficiency fully automatic waste tire pyrolysis plant

1. Feeding in every second and minute,automatic ejiecting wastes residue,Fuel product day and night

2. High efficiency fully automatic waste tire pyrolysis plant, advanced technology, full automation.

3. Large capacity(10-30tons tire/plastic per day), high oil yield, good oil quality, high profit.

4. Low cost in operation. No need energy to heat the reactor, generated syn gas is enough, less manpower.

5. High quality and environment, to meet your strict emission standards.

6. Safety. Mature safety devices, such as alarm for over temperature and pressure, auto pressure releasing system, extra gas recycling system and fire fighting device, guarantee 100% safety in the continuous tyre to oil recycling process.

The raw materials and oil yield of different input

Our High efficiency fully automatic waste tire pyrolysis plant can handle a variety of common tyres in life, and different tyres have different oil yield.

Working processing of High efficiency fully automatic waste tire pyrolysis plant

To keep continuous feeding and discharge system, it requires the waste tires should be in small size. So before continuous pyrolysis process, the waste tires should be shredded into small pieces. And to avoid the steel wire mix with carbon black after pyrolysis process which is difficult to separate, it's better to remove the steel wire from waste tires at first.

As for waste tyre continuous pyrolysis plant detailed process, please check as below:

1. Collect waste tires: All kinds of waste tires are available, from small car tires to big OTR tires.

2. Remove steel wire: Use a steel wire pulling machine to pull out the steel wire from waste tires. The steel wire pulling machine is operated automatically, which only need one work for operation.

3. Shred tires: Use a specialized tire shredder to process big whole tires into 3-5cm small pieces for easy feeding. The tire shredder is a single and fully automatic shredding system, which can be directly connected to the feeding system of the continuous pyrolysis plant, which no need any transfer process.

4. Continuous pyrolysis process: Shredded tires go into the Continuous scale tire pyrolysis unit, will firstly go through a mutiple pyrolysis reactor system to be pyrolyzed into oil gas. And oil gas will be cooling down to liquid oil through the cooling system. The residues (carbon black) will be pushed by continuous feeding tires to the carbon black dischrge system for discharge.

During the continuous pyrolysis process, reactor heating is by indirect hot air heating, which will not damage reactor so much, thus to keep long usage life of the reactors. And since steel wire already removed from waste tires before pyrolysis processs, thus no need any magnetic separation system to process the carbon black and keep the factory clean. This carbon black product can be directly collected or transported for recycle use or further treatment.

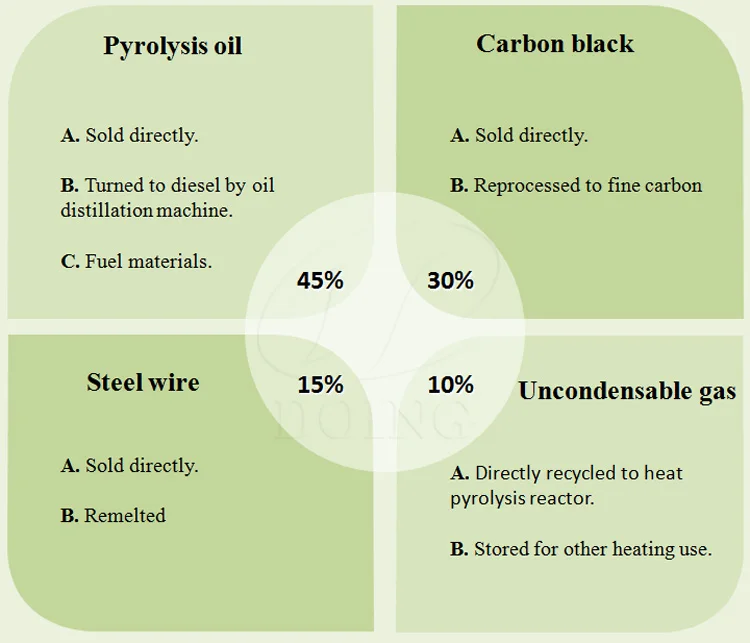

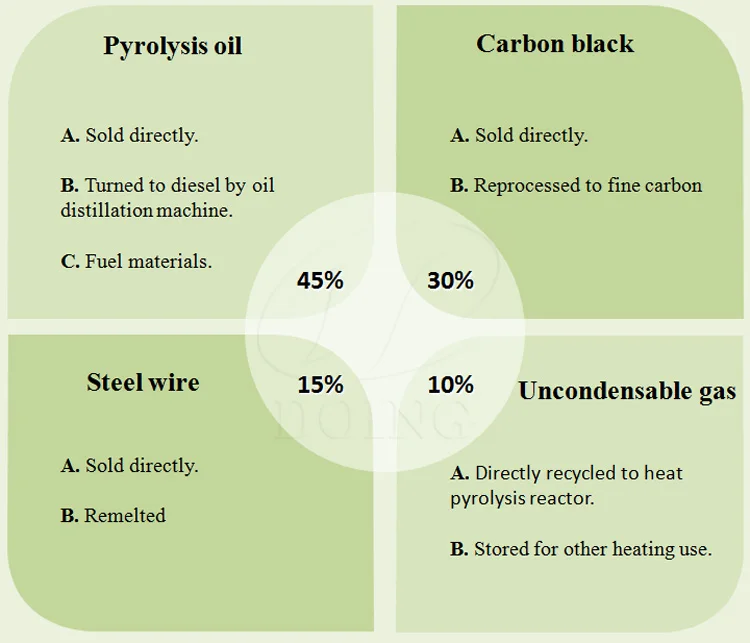

Final product and application of High efficiency fully automatic waste tire pyrolysis plant

Fuel Oil (45% to 52%)

The main application of oil products produced by our waste tyre continuous pyrolysis plant is the fuel oil that is wide used for industrial and commercial purposes. 45% to 52% oil of the amount of recycled scrap tyres can be carried with licensed tanker trucks.

Carbon Black (30%)

The second product of waste tyre continuous pyrolysis plant is carbon black. The quantity of carbon black is about 30% to 35% according to tyre quality. The use of carbon black is as a chemical strengthener in rubber and coloring agent in pigment industries. This carbon black price is very competitive compared to petroleum carbon black, so our pyrolysis carbon black is good option in stead of petroleum carbon black.

Steel Wire (12% to 15%)

The third product of waste tyre continuous pyrolysis plant is steel wire, the quantity of steel wire is about 10% to 15% according to tyre quality. It is very easy to sell steel wire scrape in local market.

Oil Gases (About 10%)

We get about 10% oil gases during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.

Packaging & Shipping

Packing & delivery of High efficiency fully automatic waste tire pyrolysis plant

By now we have delivered hundreds of fully automatic continuous type waste tire pyrolysis plant to about 60 countries:

Africa: Nigeria, Congo, Egypt, Uganda;

Europe: Romania, Poland, Italy, Macedonia, Albania, Turkey;

Asia: Malaysia, Pakistan, India, Thailand, Iran, Bangladesh, Lebanon, Jordan;

America: Mexico, Ecuador, Haiti, Guatamala, Aruba, Panama, Jamaica, etc.

FAQ

FAQ of High efficiency fully automatic waste tire pyrolysis plant

1. Are you manufacturer or trade compnay ?

We are the manufacturer, which have more than 10 years experience specialized in all kinds of waste recycling machinery.

2. Where is your factory ?

Our factory is locate in the industrial area, which only takes about one and half hour from Zhengzhou national airport to our factory. And we have the office very near to the airport which can pick you up directly from the airport to our office or factory. Welcome your visiting!!

3. How does your factory do regarding quality control ?

Quality is priority, since establishement, we keep strictly requirements about the quality with using X-Ray to test every section of the products, so we gain high praise from our customers ,all product have to pass strict inspection before they were sent out.

4. How about your after-service ?

We will provide one year free warranty for our machine, and after machine delivery, we have the engineers which can be sent to your site for machine installation, commissioning and traning your workers. You also can feel free to contact us, when you have any questions about our machine.

5. How long does will take you to delievery ?

A. In stock, within 15 days after received the advanced payment;

B. Out of stock, within 25 days after received the advanced payment.

We are in the central part of China, and it just takes 30 minutes' driving from the airport to our office. Every month, we receive many customers from different countries coming to visit our factory. If you are now looking for a new project, welcome to visit us!

Ubicación : Room 1408, 14th Floor, Building 9, No.133 Yaozhai Road, Jinshui District Zhengzhou City / Henan Province 450000 China, 450000 Zhengzhou,

Persona a contactar : Waste tyre pyrolysis plant DOING, +8613526692320