Cemented carbide material is a kind of alloy material which is made of hard compounds of an insoluble metal and binder metal by powder metallurgy process. Binder metals are usually iron group metals, commonly cobalt and nickel. The hardened phase is the carbide compound of transition metal in the periodic table of elements, such as tungsten carbide, titanium carbide, and tantalum carbide. Their hardness is very high, and their melting point is above 2000 ℃, some even more than 4000 ℃. In addition, the nitrides, borides, and silicides of transition metals have similar properties, and they can also act as hardening phases in cemented carbides. The existence of hardened phase determines the high hardness and wear resistance of the carbide alloy. Among all cemented carbides, Betalent carbide is mainly focusing on tungsten carbide cobalt alloy and tungsten carbide nickel alloy.

The hardness of cemented tungsten carbide alloy depends on WC content and grain size, that is, the higher the WC content and the finer the grain size, the greater the hardness. The toughness of carbide chemical composition is determined by the binder metal. The higher the content of binder metal, the greater the bending strength, tougher.

Cemented Carbide Properties

Cemented carbide generally has a series of excellent properties, such as high hardness, wear resistance, good strength and toughness, heat resistance, corrosion resistance, etc., especially its high hardness and wear resistance, which is basically unchanged even at 500 ℃, and still has high hardness at 1000 ℃, and the sintering temperature is 1460 °. The property of tungsten carbide chemical composition is stable, and there is no obvious chemical reaction in contact with workpiece or environment cleaning materials, labor protection materials (including grinding fluid, cutting fluid, grinding wheel, silicon carbide grinding wheel, various lubricants, tartaric acid and other common materials used in centerless grinding or other deep machining processes).

As one of the professional tungsten carbide manufacturers, BETALENT is able to provide you cemented carbide products of high quality.

Cemented Carbide Products

Carbide Rod

Heading Die Blank

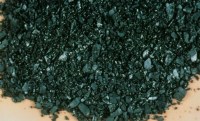

Ground Carbide

Wear Parts

Cemented Carbide Application

Cemented carbide ( tungsten carbide ) is widely used as cutting tool materials, such as turning tools, milling cutters, planers, drills, boring cutters, etc., for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone materials, and ordinary steel, as well as for cutting heat-resistant steel, stainless steel, high manganese steel, tool steel and other difficult-to-cut materials.

Cemented carbide ( tungsten carbide ) is also widely used in molds and machine wear parts which need excellent wear resistance. For example heading die core, punch pins in the fastener industry, wire drawing die core, wire tube core, lock core, various irregular die core, and nozzles, seal rings, roller, bushing, and gear hob blank, etc.

Xiamen Betalent Carbide Co.,Ltd is a carbide producer, which focus on designing, producing and selling cemented carbide products, we provide carbide components, carbide chemical composition, carbide bar stock, tungsten carbide raw material, carbide alloy, carbide cutting tools for sale. Want to know more? Please contact us.

Ubicación : 79#209, Xianggang Wuli, Haicang district, Xiamen City, Fujian,China, 361026 Xiamen,

Persona a contactar : Zhang Silin , 0086(592)6082759