|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

B2B Servicios

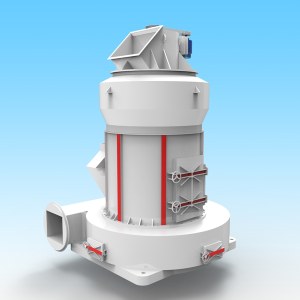

GK1720A Pendulum Grinding Mill

|

|

Model |

Max Feeding Size |

Product Fineness (mash) |

Capacity |

Gross Weight |

Total Installed Power |

|

GK2500 |

≤35mm |

80-325mesh |

15000-50000kg/h |

66t |

625kw |

|

GK2150 |

≤35mm |

80-325mesh |

10000-40000kg/h |

64t |

548kw |

|

GK1720A |

≤35mm |

80-325mesh |

6000-25000kg/h |

49t |

424.5kw |

|

GK1620A |

≤30mm |

80-325mesh |

3000-18000kg/h |

34.5t |

329.5kw |

|

GK1500 |

≤20mm |

80-325mesh |

2500-16000kg/h |

31t |

242kw |

|

5R4128 |

≤20mm |

80-325mesh |

2000-14000kg/h |

28.5t |

220kw |

|

5R4125 |

≤20mm |

80-325mesh |

2000-14000kg/h |

28.5 |

202kw |

|

GK1280 |

≤20mm |

80-325mesh |

1500-10000kg/h |

19t |

133.5kw |

|

4R3220 |

≤20mm |

80-325mesh |

1000-7000kg/h |

14.6t |

101.5kw |

Preparation before operation of GK1720A Pendulum Grinding Mill:

Check that the supply voltage meets corresponding requirements. Don't start the machine when the voltage is lower than 360 v. Check the electric circuit in the light of drawing.

Check all joint bolts for tightness, especially the bolts in host chamber.

Check drive belt for looseness and tightness. The mainframe can rotate freely by moving it with hands. Check grinding rollers for flexible movement. The buffer spring above the roller assembly in the main unit should be screwed up to 185mm(see drawing 2); the length of four spring should be kept on the same size.

See that governor valve of inlet pipe air blower is in "off" position(it is automatically controlled by the pneumatic valve. Before start the blower, power on it to test it first. Normally the positioning pin is fixed to the positioning hole. After electromagnetic switch valve is energized, under the effect of air pressure, the cylinder activities section stretches out and drive the connecting rod, then the valve plate is open. When it is powered off, the valve is closed.)( see drawing 4)

Check the chain of the elevator for looseness and tightness.

Lubricate all parts according to the lubrication table. Lubricants are filled before use.The grease is clean. Check all the joints for oil leakage.

Regulate the discharge opening of jaw crusher in line with the nature of materials. The particle size is less than 35 mm.

Check motors for rotating direction.

a. The main engine has a clockwise running (looking down from above).

b. The turbine blade of the separator has a clockwise running(looking down from above).

c. The air blower rotates clockwise(looking from belt wheel end).

Check pulse dust collector:

Start induced draft fan. Check shell and discharge valve for air leakage.

Keep the pressure of air compressor piping system on 0.5-0.7 MPa. Check

Persona a contactar : Zeng Ralap , 0773 6812095

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de GK1720A Pendulum Grinding Mill Buscar en la categoria : B2B Servicios Buscar en la categoria : pendulum, gk1720a, grinding, mill |

Friday 04 March 2016

Cantidad : 150 - Precio : 280,00 €

Vous vérifiez vos dizaines et des dizaines de fois par jour iPhone, probablement plus. La saisie d'un mot de passe chaque fois que vous ralentit juste. Mais vous le faites parce que faire en sorte que personne d'autre n'a accès à votre iPhone est important. Avec iPhone 5s, entrer...

Electronics Design Services

- CM23 2JP - Hertfordshire

- +447405858765

Thursday 20 March 2014

Cantidad : 3000 - Precio : 3,50 €

Descubra nuestra nueva colección de traje (ropa) mujer a partir de 3,50€ sobre el sitio. www.grossiste-en-live.fr Pago rápido y seguro Son mayorista en traje(ropa) mujer en internet, usted directamente puede pedir (mandar) sobre el sitio en pago tranquilizado por CB...

DLB DISTRIBUTION LTD

- N17GU - Londres

- +34 6 57 30 01 30

Saturday 20 February 2016

Cantidad : 1000 MT PE - Precio : 400 usd per mt CIF

Dried Pomegranate seed,Semen malogranati,Semen punici granati,Punica granatum,Punica malus,Punica florida,Punica grandiflora,Punica nana,Punica spinosa,Shiliu,Shi liu in high quality. Advantage 1 We are a manufacturer and exporter specializing in herb and herbal tea ingredient...

Khun Jack Partnership Ltd

- 5000 - Chaing Mai

- +66 9 68 75 20 43