|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Bienes de equipo

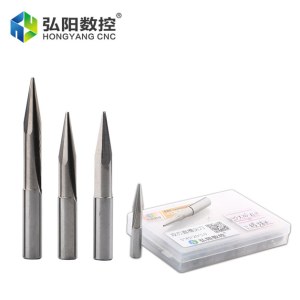

Double-edged Straight Flute Sharp Knife |

|

product name: |

Double-edged straight flute sharp knife |

|

product material: |

Tungsten steel material |

|

Product Specifications: |

3.175/4/6 |

|

Applicable materials: |

Hardwood, solid wood, MDF, etc. |

|

The main function: |

No polishing, non-stick knife, large capacity chip removal |

|

Use the machine: |

Woodworking advertising engraving machine, CNC machining center |

Features of Double-edged Straight Flute Sharp Knife

Larger chip chute with larger capacity for faster chip evacuation.

2. The overall tungsten steel fine grinding process, high wear resistance, high hardness, sharp knife.

- The cutting edge is sharp, and high-precision processing can be performed. There is no smoke, no smoke and no burrs during processing.

|

M0DEL |

SHK |

angle |

TIP |

OVL |

M0DEL |

SHK |

angle |

TIP |

OVL |

M0DEL |

SHK |

angle |

TIP |

OVL |

|

3.175*20*0.1 |

3.175 |

20° |

0.1 |

38 |

4*20*0.4 |

4 |

20° |

0.4 |

45 |

6*20*0.3 |

6 |

20° |

0.3 |

50 |

|

3.175*20*0.2 |

3.175 |

20° |

0.2 |

38 |

4*22*0.4 |

4 |

22° |

0.4 |

45 |

6*20*0.4 |

6 |

20° |

0.4 |

50 |

|

3.175*20*0.3 |

3.175 |

20° |

0.3 |

38 |

4*30*0.3 |

4 |

30° |

0.3 |

50 |

6*20*0.5 |

6 |

20° |

0.5 |

50 |

|

3.175*20*0.5 |

3.175 |

20° |

0.5 |

38 |

4*40*0.1 |

4 |

40° |

0.1 |

40 |

6*20*0.6 |

6 |

20° |

0.6 |

50 |

|

3.175*30*0.1 |

3.175 |

30° |

0.1 |

38 |

4*40*0.2 |

4 |

40° |

0.2 |

41 |

6*20*0.8 |

6 |

20° |

0.8 |

50 |

|

3.175*30*0.2 |

3.175 |

30° |

0.2 |

38 |

4*40*0.3 |

4 |

40° |

0.3 |

40 |

6*20*0.8 |

6 |

20° |

0.8 |

50 |

|

3.175*30*0.3 |

3.175 |

30° |

0.3 |

38 |

4*45*0.1 |

4 |

45° |

0.1 |

38 |

6*20*0.4 |

6 |

20° |

0.4 |

45 |

|

3.175*45*0.1 |

3.175 |

45° |

0.1 |

38 |

4*45*0.2 |

4 |

45° |

0.2 |

35 |

6*20*0.4 |

6 |

20° |

0.4 |

50 |

|

3.175*45*0.2 |

3.175 |

45° |

0.2 |

38 |

4*45*0.3 |

4 |

45° |

0.3 |

32 |

6*20*0.4 |

6 |

20° |

0.4 |

70 |

|

3.175*45*0.3 |

3.175 |

45° |

0.3 |

38 |

4*60*0.1 |

4 |

60° |

0.1 |

32 |

6*20*0.4 |

6 |

20° |

0.4 |

80 |

|

3.175*60*0.1 |

3.175 |

60° |

0.1 |

38 |

4*60*0.2 |

4 |

60° |

0.2 |

32 |

6*20*0.4 |

6 |

20° |

0.4 |

100 |

|

3.175*60*0.2 |

3.175 |

60° |

0.2 |

38 |

4*60*0.3 |

4 |

60° |

0.3 |

32 |

6*20*0.4 |

6 |

20 |

0.4 |

120 |

|

3.175*60*0.3 |

3.175 |

60° |

0.3 |

38 |

4*90*0.1 |

4 |

90° |

0.1 |

32 |

6*20*0.4 |

6 |

20° |

0.4 |

150 |

|

3.175*90*0.1 |

3.175 |

90° |

0.1 |

38 |

4*90*0.2 |

4 |

90° |

0.2 |

38 |

|

|

|

|

|

|

3.175*90*0.2 |

3.175 |

90° |

0.2 |

38 |

4*90*0.3 |

4 |

90° |

0.3 |

39 |

|

|

|

|

|

|

3.175*90*0.3 |

3.175 |

90° |

0.3 |

38 |

|

|

|

|

|

|

|

|

|

|

Jinan Hongyang CNC machinery co., Ltd is one of global famous cnc spare parts suppliers. We provide double flute straight bit, 2 flute straight end mill, 2 flute straight cut router bit, solid carbide 2 flute straight end mill, double flute straight router bit, double fluted router bit, CNC Router Parts, CNC Router Bits, cnc machine components and so on. Want to know more? Please contact us.

Persona a contactar : cncrouter hy, 0531 67888071

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de Double-edged Straight Flute Sharp Knife Buscar en la categoria : Bienes de equipo Buscar en la categoria : edged, sharp, straight, flute, knife, double |

Friday 15 December 2017

online katalogOEM PART NO DESCRİPİTİON 66072 Crown Wheel and Pinion FOR CARRARO 13X30 66941 Crown Wheel and Pinion 15x37 2277448 CATERPİLLAR AİR FİLTER OUTER 2277449 CATERPİLLAR AİR FİLTER İNNER 01/117901 FAN BELT 01/124403 FAN BELT 01/124404 02/100073 Oil Filter Canister Type, MEDİUM...

ANAC MAKINA CO LTD STI

- 34800 - İSTANBUL

- +905069691531

- +9005069691531

Tuesday 17 February 2026

Cantidad : 80000 Ream - Precio : $0.79/Ream for 8000

ESPECIFICACIONES - Tamaño de hoja: 210mm x 297mm / 297mm x 420mm Normas Internacionales de papel Tamaño (ISO) A4 / A3 - Calidad: Importado 100% pulpa de madera virgen - Blancura: 102-104%, blanco natural - Clasificación: A - Espesor: 106cm - Capacidad: High Speed Copiado 100 ppm...

NATH LAOH LTD

- 50100 - Chiang Mai

- +66 9 95 35 59 56

Saturday 15 November 2014

Vendo Komori Sprint S 228 II, Año 1998 52x72 - 2 Colores, S-APC, Mojado Komorimatic, Refrigeración Technotrans, Marcador Continúo, Cilindros de Impresión Cromados, salida a pila baja, Pulverizador … - La máquina está en MUY BUENA Condición - Fotos : http://www.acsdif.fr/script/sp/fic_machine...

ACS DIFFUSION s.a.s.

- acsdiffusionsa

- 42952 - Saint-Etienne

- 0033 (0)4 77 92 77 88

- 06 10 63 37 83