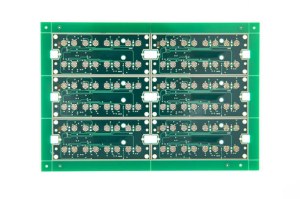

We can provide you with up to 64 layers, 12oz copper, HDI, high frequency, high TG, flex, MC pcb from prototype to mass production.

As a rigid pcb manufacturer, Fastlink Electronics offers the highest quality printed circuit boards at the most competitive pricing. Whether you need a few quick-turn PCB prototypes or mass production, our world-class manufacturing can meet your specialized PCB needs with rigid pcb fabrication assembly.

Combining years of experience with the latest in high-tech manufacturing efficiencies allow our pricing to be among the most competitive. Our boards are manufactured based on IPC guidelines and comply with ISO 9001: 2015, UL, and RoHS standards.

Rigid PCBs, or Printed Circuit Boards, are a type of circuit board that is commonly used in electronic devices. A rigid pcb assembly is made up of a flat sheet of insulating material, such as fiberglass or epoxy resin, with conductive pathways etched onto its surface. These pathways, also known as traces, connect different electronic components and allow for the flow of electrical signals throughout the board.

Rigid PCBs are popular due to their durability, reliability, and the ability to create complex circuits in a small area. They are used in a wide range of industries, including consumer electronics, medical devices, aerospace and defense, and industrial automation.

There are several types of rigid PCBs, including single-layer, double-layer, and multi-layer PCBs. Single-layer PCBs have only one layer of conductive pathways, while double-layer PCBs have two layers. Multi-layer PCBs can have four or more layers, and are used for complex circuits that require more routing options.

Rigid pcb board design is an important aspect of the PCB manufacturing process. The design of a PCB determines the overall performance and functionality of the electronic device. Here are some key considerations when designing a rigid PCB:

PCB Layout Guidelines:

The layout of the PCB is critical for ensuring proper functionality and reliability. Proper layout includes the placement of components, the routing of traces, and the spacing between them. The layout should also take into account the heat dissipation and electromagnetic interference (EMI) considerations.

Components and their Placement:

The placement of electronic components on the PCB is essential for proper functionality and reliability. The components should be placed in such a way that they are easily accessible for installation, maintenance, and repair. The placement should also allow for proper heat dissipation and EMI considerations.

Traces and Routing:

Traces are the conductive pathways that connect electronic components on the PCB. Proper routing and spacing of traces ensures that the signals flow smoothly and without interference. The routing should also take into account the power requirements of the components and the noise reduction.

Power and Ground Planes:

The power and ground planes are essential for proper power distribution and noise reduction. The planes should be designed to minimize the impedance and provide a stable reference voltage.

Signal Integrity:

Signal integrity is critical for the proper functioning of the electronic device. Proper design includes minimizing signal distortion, crosstalk, and timing issues.

Design for Manufacturability:

The design should take into account the manufacturing process and should be optimized for efficient and cost-effective production.

Design for Testability:

The design should also take into account testing and inspection requirements to ensure proper functionality and reliability.

key Considerations when Designing a Rigid PCB

What Are The Applications For Rigid PCBS

Rigid printed circuit boards are one of the most common circuit boards in electronic devices and have several typical applications. These include:

Use as motherboards for desktop and laptop computers

File servers and storage devices

It can be found on cell phones and other portable devices

Used in medical devices such as CT scans, x-rays, and pacemakers

Found in automobiles

Used as signal repeaters and GPS for mobile phones and other devices

Tips for Rigid PCB Production

Here are some tips for producing high-quality rigid PCBs:

01.

Choose the right material

The choice of materials plays a critical role in the quality of the PCB. Make sure to select materials that meet your PCB's requirements, such as thermal conductivity, dielectric constant, and mechanical strength.

02.

Plan your layout

Proper planning of the PCB layout is crucial for ensuring signal integrity and reducing noise. Consider factors such as trace width, spacing, and via placement to minimize interference and crosstalk.

03.

Use high-quality software

Use reputable PCB design software to create your PCB layout. This ensures accuracy and consistency in the placement of components, traces, and vias.

04.

Practice good design for manufacturing (DFM)

Design for manufacturing involves creating a PCB layout that takes into account the capabilities and limitations of the manufacturing process. For example, avoid placing components too close to each other, as this can make assembly difficult.

05.

Choose the right fabrication process

Different fabrication processes have different strengths and weaknesses. Research the different options available to you and choose the one that best suits your needs.

06.

Inspect your PCBs

Once your PCBs are fabricated, inspect them carefully to ensure they meet your specifications. Check for defects such as shorts, open circuits, and misaligned components.

07.

Test your PCBs

Testing your PCBs is essential to ensure they function as intended. Use appropriate testing equipment and procedures to verify the performance of your PCB.

Flex Vs Rigid PCBs

Flex and rigid PCBs are two different types of circuit boards used in electronic devices. Here's a comparative analysis between the two:

Flexibility: As the name suggests, flex PCBs are flexible, whereas rigid PCBs are not. Flex PCBs can bend and twist, making them ideal for use in devices with irregular shapes or where space is limited. Rigid PCBs are more rigid and inflexible, making them suitable for devices that require a stable and sturdy base.

Cost: Flex PCBs are generally more expensive than rigid PCBs due to the additional manufacturing steps and materials required for their flexibility. Rigid PCBs are simpler to manufacture, which makes them more cost-effective.

Size and Weight: Flex PCBs are typically thinner and lighter than rigid PCBs, making them ideal for devices that require a smaller size and lower weight.

Design Flexibility: Flex PCBs can be designed to fit into complex shapes and spaces, making them ideal for devices with unique form factors. Rigid PCBs, on the other hand, are typically designed in a rectangular shape and have limited design flexibility.

Reliability: Both flex and rigid PCBs can be reliable if designed and manufactured properly. However, flex PCBs may be more prone to damage due to their flexibility, which can lead to failure over time. Rigid PCBs are generally more robust and less susceptible to damage.

Manufacturing Process: Flex PCBs require additional manufacturing steps, such as the use of flexible materials, specialized equipment, and a different etching process. Rigid PCBs are simpler to manufacture, which makes them faster and more cost-effective to produce.

Application: Flex PCBs are typically used in applications where flexibility and space are critical, such as in wearable devices, medical devices, and aerospace applications. Rigid PCBs are used in a wide range of applications, including consumer electronics, industrial automation, and automotive applications.

All in all the choice between flex and rigid PCBs depends on the specific requirements of the electronic device. Flex PCBs are ideal for applications where flexibility and space are critical, while rigid PCBs are suitable for devices that require a stable and sturdy base.

Flex Vs Rigid PCBs

Get in Touch to Discuss your PCB Project

At Fastlink-electronics, we provide a comprehensive range of PCB services to meet all your needs. Whether you require rigid PCBs, HDI PCBs, or PCB prototypes, we have you covered. We understand that choosing the right type of PCB for your product can be a daunting task, but our team of experts is here to help.

If you are unsure which PCB is best suited for your product, we invite you to get in touch with our team. We will be happy to offer our professional advice and guidance to help you make an informed decision. Additionally, we can provide you with a quote tailored to your specific requirements.

At Fastlink-electronics, we are committed to providing high-quality PCB services that meet your needs and exceed your expectations. Contact us today to learn more about our PCB services and how we can help you achieve your goals.

Now the price of pcb fabrication assembly is reasonable, if you have needs, please contact us.