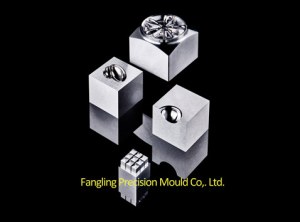

Precision OEM CNC milling parts

Completed by CNC milling and forming grinding

Accuracy of our custom CNC milling metal parts can be achieved within ±0.002mm.

Main products: all kinds of precision parts, connectors, fixture, standard parts, mold design, development and manufacturing.

Business projects: precision plastic molding grinding, precision EDM, CNC wire cutting, precision milling machining.

Independently research and develop and design automation production machine, to solve the human bottleneck problem and production obstacles for clients.

Customized customer demand, research and develop automated production in accordance with the customer production planning.

Automated assembly production, share client capacity, OEM production to finish customer delivery.

We cooperated with the businesses from different countries and regions

Japan ABLE, Belgian Accuritas, Taiwan Cheng Wei Precision Industry Co., Ltd., Cheng Ming Electronic Science and Technology Co., Ltd. (Dongguan)

Our company wants to establish long-term cooperative relationship with the following types of foreign enterprises:

Electronics, automotive, electrical machine, electrical equipment, instrumentation, home appliances, communications and other industries.

DESCRIPTION OF

CNC HIGH-SPEED MILLING MOLD PARTS

What Are The Main CNC Milling Parts

Column and base

The column and base support the remaining parts of a milling machine, and the spindle is lubricated by an oil reservoir and pump in the column. The base supports the column and includes a coolant reservoir and a pump for coolant delivery during machining operations.

Knee

The gearing mechanism is housed inside a knee. Dovetail ways connect the knee to the column. A vertical positioning screw, often known as an elevating screw, supports and adjusts it. The elevating screw moves the knee up and down by raising or lowering the lever using a hand or power feed.

Saddle and Swivel Table

The table is supported by the saddle, which is on the knee. In horizontal milling m/c, the saddle slides on a horizontal dovetail on the knee, and the dovetail is parallel to the spindle's axis. The saddle swiveled (revolved) horizontally in both directions, and the swivel table was attached to it.

Spindle

A milling machine's cutting tools are held and driven by the spindle. It is supported by the column and is positioned on bearings. An electric motor drives the spindle using gear trains located on the column. The spindle face, close to the table, is machined with an internal taper. The front face has two keys that give a positive drive for the cutter holder or arbor.

Table

A table is a rectangular casting that sits on the saddle's top. The table is used to keep the work in place or to hold work-holding equipment. Several T-slots are available for storing work and work-holding devices (jigs and fixtures). It can be powered or operated by hand. It engages and turns the longitudinal hand crank to move the table by hand. It engages longitudinal direction feeds control lever to move it by power.

Over Arm/ Overhanging Arm

On the upper face of the column, there is an overarm, which is a horizontal beam. It could be a single casting that slides on the top face of the column's dovetail manner.

Ram

In a vertical milling machine, the ram is an overhanging arm. The milling head is attached to one end of the ram, positioned on the top of the column.

As a precision molding company, we will do our best to meet all the needs of customers.

Ubicación : No.10 Hongshi Rd., No.1 Industrial Zone, Lu Dong Management Zone,Humen Town, DongGuan City, Guangdong province, 523935, China, 523935 Humen,

Persona a contactar : mold Fangling, +76 9 85 55 86 31