Industrial Roller Bearings for Sale

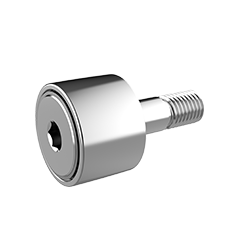

Track Roller

Deep Groove Ball Bearing

Self-aligning Ball Bearing

Angular Contact Ball Bearing

Thrust Ball Bearing

Needle Roller Bearing

Cylindrical Roller Bearing

Spherical Roller Bearing

Tapered Roller Bearing

Thrust Roller Bearing

Crossed Roller Bearing

Slewing Ring

Pillow Block Bearing

Plain Bearing

As a professional China bearing company, we are committed to providing our clients with various wholesale roller bearing types, convenient transmission components, technical services, and solutions.

Depending on the applications of our clients, we offer different types of ball bearing and transmission components, such as roller bearings for logistics equipment, crossed roller bearings and slewing bearings for robot arms and needle roller bearings for food filling equipment. Feel free to consult us for THB industrial bearings types.

Our bearing products conform to German DIN standard, American ANSI standard and Japanese JIS standard and are suitable for different applications.

We also offer customized wholesale bearing products for our clients. You can tell our professional application engineers what you need and they will provide you with professional technical services.

What are the Difference between Ball Bearing and Roller Bearing?

Ball bearings and roller bearings are both rolling bearings.

Rolling bearings are all types of bearings that can transmit controlled motion from one object to another with minimal friction by rolling balls or rollers.

Most rolling bearings are used to make the shaft relative to some fixed structure to do rotational movement (deep groove ball bearings, angular contact ball bearings, cylindrical roller bearings and tapered roller bearings, etc.), while some other rolling bearings are used for parallel movements, i.e. linear motion relative to a fixed direction of a stationary shaft (such as the roller bearings used as rollers).

Ball bearings are point-contacting bearings; that is, each ball makes contact with the track at a very small point - theoretically a single point. Such bearings are designed to ensure that the slight deformation of the balls as they roll in and out of the load area could not exceed the yield point of the material and that the balls in the unloaded positions could return to their original shapes.

Similar to ball bearings, roller bearings have linear contact rather than point contact, giving them a greater load-carrying capacity and higher vibration resistance. The rollers have different shapes, namely, cylindrical, spherical, tapered and needle shapes.

Ball bearings or roller bearings

In general, if the spaces occupied by the bearings are similar, ball bearings are used for applications with higher speeds and lower loads, while roller bearings have better performance in applications with impacts and heavy loads.

Ball bearings are usually sold as components, their parts are not separable from each other and they can simply be replaced as assemblies.

Roller bearings are less standardized, especially for applications that require separate inner and outer rings, and it is difficult to ensure that the roller bearings made by different manufacturers can be interchanged. Therefore, clients need to consult the manufacturers' track roller bearing catalogues to select the proper industrial bearing types for their applications.

Ubicación : 205,Building 9,No.589,Quwu Road,Minhang District,Shanghai,China, 200241 Shanghai,

Persona a contactar : Zhu Helen, 021 54846072