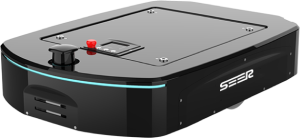

AMB Series Unmanned Chassis

Precio : 1000-6000USD

AMB Series Unmanned Chassis AMB (Auto Mobile Base) series unmanned chassis, a universal chassis designed for the mobile robots, provides some features such as map editing and localization navigation. It provides abundant extent interfaces such as I/O and CAN to mount various upper modules together with powerful client software and dispatching systems to help users quickly complete manufacture and application of mobile robots. There are four mounting holes on the top of the AMB series unmanned chassis, which supports arbitrary expansion with jacking, rollers, manipulators, latent traction, display, etc. to achieve multiple applications of one chassis. AMB together with SEER Enterprise Enhanced Digitalization can realize the unified dispatching and deployment of hundreds of AMB products at the same time, which greatly improves the intelligent level of internal logistics and transportation in the factory.

Descriptions

Descriptions of AMB Series Unmanned Chassis

Rich features available at any time

Comprehensive and excellent standard features and rich and practical advanced features help clients easily achieve intelligent logistics.

Multi-specification platforms available for expansion

It offers a wide range of expansion platforms from 150 kg to 500 kg to meet the load and scenario requirements of different industries. It can also be used with manipulators, rollers, jacking, latent traction, pan/tilt, display screen, etc. to achieve multiple applications with one chassis.

±5 mm, efficient and accurate

Laser SLAM algorithm is used to achieve high-precision localization, with the laser non-reflective repeated locating accuracy within ±5 mm, enabling seamless docking between mobile robots and between mobile robots and humans, and efficient flow of cargoes among various points. Note: Actual values depend on environmental conditions

Stable navigation for safety and reliability

Network stability When there are multiple APs at the user site, the mobile robot can perform fast and stable roaming switching among multiple APs with optional industrial-grade Wifi client module that supports roaming to ensure the stability of the scheduling system connection.

Navigation stability Multiple navigation approaches ensure stable operation of the mobile robot.

3D obstacle avoidance A 3D vision sensor is added to identify and detect some three-dimensional obstacles (such as too low or too high obstacles, potholes on the ground, etc.) and choose to stop or bypass according to the configuration.

Easy deployment and visible management

SEER Enterprised Enhanced Digitalization, SEED easily enable mobile robot operation, dispatching and information management, and seamlessly connect with the plant's MES system to truly achieve intelligent logistics.

Specifications

Specifications of AMB Series Unmanned Chassis

AMB-150 | AMB-150-D

Basic parameters

|

Navigation method |

Laser SLAM |

|

|

Drive mode |

Two-wheel differential |

|

|

Shell color |

Pearl white/Pearl black/Customized Color |

|

|

L*W*H |

800*560*200mm |

|

|

Rotation diameter |

840mm |

|

|

Weight (with battery) |

66kg |

|

|

Load capacity |

150kg |

|

|

Chassis ground clearance |

25mm |

|

|

Laser scanning height |

228mm |

|

|

Network |

Ethernet / Wi-Fi 802.11 a/b/g/n/ac |

|

|

Temperature and humidity range |

TEMP: 0-50℃ / RH: 10-90%, no compression, no condensation |

|

|

IP rating[1] |

IP20 |

|

Performance parameters

|

Passability (slope/step/gap)[2] |

< 5%/5mm/10mm |

|

|

MIN. passable width |

700mm |

|

|

Navigation position accuracy[3] |

±5mm |

|

|

Navigation angle accuracy[3] |

±0.5° |

|

|

Navigation speed |

≤ 1.4m/s |

|

|

Map area (single frame) |

≤ 400000m² |

|

Battery parameters

|

Battery specifications |

48V/35Ah (Ternary lithium) |

|

|

Comprehensive battery life |

12h |

|

|

Charging time (10-80%) |

≤ 2h |

|

|

Charging method |

Manual/Automatic/Quick change |

|

|

Battery cycles |

> 500 |

|

Extended interfaces

|

Power DO |

Seven-way (total load capacity 24V/2A) |

|

|

DI |

Ten-way (NPN) |

|

|

E-stop interface |

Two-way output |

|

|

Wired network |

Three-way RJ45 gigabit ethernet |

|

Configurations

|

Number of lidar |

1 or 2(P+F R2000-HD) |

|

|

HMI display |

√ |

|

|

E-stop button |

√ |

|

|

Buzzer |

√ |

|

|

Speaker |

√ |

|

|

Atmosphere light |

√ |

|

|

Bumper strip |

× |

|

Features

|

Basic features[4] |

√ |

|

|

Wi-Fi roaming |

√ |

|

|

Automatic charging[5] |

√ |

|

|

Shelf recognition[6] |

√ |

|

|

Laser reflector navigation |

〇 |

|

|

3D obstacle avoidance[7] |

〇 |

|

Certifications

|

EMC/ESD |

√ |

|

|

UN38.3 |

√ |

|

|

RoHS |

√ |

|

|

REACH |

√ |

|

AMB-300 | AMB-300-D

Basic parameters

|

Navigation method |

Laser SLAM |

|

|

Drive mode |

Two-wheel differential |

|

|

Shell color |

Pearl white/Pearl black/Customized Color |

|

|

L*W*H |

1000*700*200mm |

|

|

Rotation diameter |

1040mm |

|

|

Weight (with battery) |

144kg |

|

|

Load capacity |

300kg |

|

|

Chassis ground clearance |

25mm |

|

|

Laser scanning height |

228mm |

|

|

Network |

Ethernet / Wi-Fi 802.11 a/b/g/n/ac |

|

|

Temperature and humidity range |

TEMP: 0-50℃ / RH: 10-90%, no compression, no condensation |

|

|

IP rating[1] |

IP20 |

|

Performance parameters

|

Passability (slope/step/gap)[2] |

< 5%/5mm/30mm |

|

|

MIN. passable width |

840mm |

|

|

Navigation position accuracy[3] |

±5mm |

|

|

Navigation angle accuracy[3] |

±0.5° |

|

|

Navigation speed |

≤ 1.4m/s |

|

|

Map area (single frame) |

≤ 400000m² |

|

Battery parameters

|

Battery specifications |

48V/52Ah (Ternary lithium) |

|

|

Comprehensive battery life |

12h |

|

|

Charging time (10-80%) |

≤ 2.5h |

|

|

Charging method |

Manual/Automatic/Quick change |

|

|

Battery cycles |

> 500 |

|

Extended interfaces

|

Power DO |

Seven-way (total load capacity 24V/2A) |

|

|

DI |

Ten-way (NPN) |

|

|

E-stop interface |

Two-way output |

|

|

Wired network |

Three-way RJ45 gigabit ethernet |

|

Configurations

|

Number of lidar |

1 or 2(P+F R2000-HD) |

|

|

HMI display |

√ |

|

|

E-stop button |

√ |

|

|

Buzzer |

√ |

|

|

Speaker |

√ |

|

|

Atmosphere light |

√ |

|

|

Bumper strip |

× |

|

Features

|

Basic features[4] |

√ |

|

|

Wi-Fi roaming |

√ |

|

|

Automatic charging[5] |

√ |

|

|

Shelf recognition[6] |

√ |

|

|

Laser reflector navigation |

〇 |

|

|

3D obstacle avoidance[7] |

〇 |

|

Certifications

|

EMC/ESD |

√ |

|

|

UN38.3 |

√ |

|

|

RoHS |

√ |

|

|

REACH |

√ |

|

AMB-500 | AMB-500-D

Basic parameters

|

Navigation method |

Laser SLAM |

|

|

Drive mode |

Two-wheel differential |

|

|

Shell color |

Pearl white/Pearl black/Customized Color |

|

|

L*W*H |

1000*700*200mm |

|

|

Rotation diameter |

1040mm |

|

|

Weight (with battery) |

130kg |

|

|

Load capacity |

500kg |

|

|

Chassis ground clearance |

20mm |

|

|

Laser scanning height |

228mm |

|

|

Network |

Ethernet / Wi-Fi 802.11 a/b/g/n/ac |

|

|

Temperature and humidity range |

<span style="font-family: Ca |

Persona a contactar : Gong Miya, 400 726 9969

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de AMB Series Unmanned Chassis Buscar en la categoria : Varios / Descuento Buscar en la categoria : chassis, series, unmanned |

Tuesday 03 February 2026

Cantidad : 500 - Precio : USD0.5/pc

American Pinch clamps Factory in China The Supplier of one of Fortune top 500 Machine, Technology, Quality from USA SAE Type SEC Stainless Steel Single Ear Pinch Clamps KSL7123 Beverage, automotive, marine, motorcycle and industrial pinch clamps. The patented 300 Series Stainless...

King Seal Fastener Technology(Anhui) Co., Ltd.

- 233010 - Bengbu

- 86 552 4193229

Wednesday 13 January 2016

Established in 2000, Focus CNC Co., Ltd. provides series of CNC Lathe Machinery, CNC Lathe, live tool CNC Lathe, mill turn Lathe and CNC turning machine. Due to our principle of “Humanity, Technology and Precision” in mind, we keep breaking through to become one leading Industry...

Focus CNC Co., Ltd.

- focus.cnc1999

- 428 - Taichung City

- +886 4 2560 6067

Tuesday 03 February 2026

Cantidad : 10 000 PIE - Precio : 2 EUROS

LOT DE TAPIS DE BAIN Quantité : 10 000 pièces Prix : 2 EUROS Bonjour, Nous sommes la société S.D.P.I.E : SOLDEUR Notre activité consiste en le rachat et la vente de lots. DESTOCKAGE D'UN LOT DE TAPIS DE BAIN Nombre de pièce : 10 000 PIECES - Prix Unitaire HT : 2 EUROS Nous...

S.D.P.I.E

- discount-pro

- 69730 - GENAY

- +33 4 72 35 91 51

- +33 6 09 42 11 81