ANCHOR CHAIN SHOT BLASTING MACHINE

The working principle for shot of anchor chain shot-blasting machine is mainly by numerous high speed abrasive flow projection to the anchor chain surface, which blast cleaning the oxides and Surface attachment from the anchor chain, and by making the surface plastic deformation to effectively improve the chain's fatigue strength and fracture resistance of corrosion.

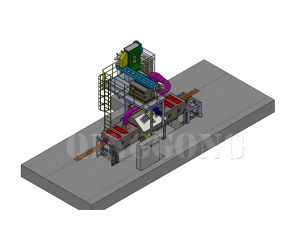

The working principle for anchor chain shot blasting machine china is mainly by numerous high speed abarsive flow projection to the anchor chain surface, which blast cleaning the oxides and Surface attachment from the anchor chain, and by making the surface plastic deformation to effectively improve the chain's fatigue strength and fracture resistance of corrosion. Main composition and structure characterized by shot blasting Chamber, sealed rooms, elevators, separators, screw conveyors, throwing Assembly, Abrasive reclaim system, elevator platform, inbound and outbound guide wheel unit, abrasive dosing unit, foundations, dust collecting systems, electrical control components.

Ship anchor chain used shot blasting machine is a tailored equiupment which design based on end user's requirements of the equipment performance, it can process φ22 to φ50 anchor chain for one-time blast cleaning.

Applications

Removal of mill and forge scale as well as rust

Removal of burrs and scales

Removal of moulding sand

Increase of surface roughness

Shot peening to increase fatigue strength

Persona a contactar : Sara Sara Li, 0532 82121566

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de ANCHOR CHAIN SHOT BLASTING MACHINE Buscar en la categoria : B2B Servicios Buscar en la categoria : blasting, anchor, shot, chain, machine |

Thursday 05 March 2026

Palets de devoluciones Action para mayoristas, liquidación profesional y exporta

Cantidad : 30000 - Precio : 0,50 €

Ofrecemos palets de devoluciones compuestos exclusivamente por artículos procedentes de la cadena Action, dirigidos a mayoristas, profesionales del liquidación, revendedores y exportadores. Estos palets de liquidación contienen productos de gran consumo no alimentarios, seleccionados por su alto potencial de reventa y rápida rotación. Detalles de la oferta: - Palets de devoluciones de gran distribución – marca Action - Aprox. 1.000 artículos por palet (80 % de los palets) - Precio medio...

TRANSIDI

- 22440 - PLOUFRAGAN

- 09 72 63 03 26

- 33(0)603670505

Friday 16 May 2014

Cantidad : 5000000 - Precio : $0.50-5/pc

Perfil De La Empresa: Totalmente equipado con avanzados cnc maquinaria, tenemos experiencias ricas para precisión fabricación piezas mecanizadas, piezas torneadas, piezas de fresado como por los dibujos para ofrecer la parte superior- muesca productos. Nuestras instalaciones de...

Xiamen Karo Co.,Ltd

- karoplastic

- 361002 - Xiamen

- 0086 592 5135406

Wednesday 15 April 2015

Cantidad : Inquiry - Precio : USD 0.8-1.5/piecs

Dimensions : 156mm x 156mm ± 0.5mm. Thickness (Si): 180μm ± 20μm / 200μm ± 20μm. Front : Silver bus bars Silicon nitride anti-reflection coating. Back : Silver bus bars Full-surface aluminum BSF. Ubicación : 5F,No.2.Sec.4.JhongyangRd,TuchengCity.Ta ipei County 236,Taiwan R.O.C...

Taiwan

- 23678 - New Taiwan City

- +886 2 22691686