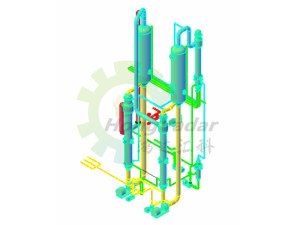

Continuous Evaporative Crystallization System

Cantidad : 1-100 Precio : USD 50000-5000000

Hongvadar is advanced in many areas, such as being the corn starch production plant and small scale tomato processing plant.

HVD-CC-T series continuous crystallisation and evaporation system is designed and developed by our factory with patent applied.

Core Of Crystallization Process Control

Design enough long crystal time according to crystal characteristics to create an environment conducive to the growth of crystal structure.

Adjust the direction of materials, control the number of microcrystals, realize the whole process control of seed generation, seed growth, elimination of microcrystals, growth of qualified particles, and timely discharge of qualified particles.

Most businesses take crystallization as the process of concentration. It is believed that the concentration reaches supersaturation, the crystal forms naturally, and there is no awareness and measures to control the crystal quality. The control of the crystal purpose is ignored, and the influence of crystallization on separation and drying is not fully considered, which makes the subsequent section treatment more difficult due to the crystallization. Therefore, the purpose of crystallization is to improve the overall yield and product quality and reduce the product production cost.

Characteristics Of Evaporative Crystallization System

Crystallisation and evaporation system/evaporation vs crystallization system is used for products with general requirements on crystal shape and size and can achieve high concentration discharging.

According to the characteristics of materials and the evaporation capacity, continuous crystallisation and evaporation system can be designed as a single-effect or multi-effect evaporative crystallization system.

The unique design of the continuous oscillatory baffled crystallizer, circulating liquid evaporator crystallizer and continuous cooling crystallizer can meet the intermittent crystallization, semi-continuous crystallization, and continuous crystallization system. It can meet the continuous feed, continuous discharge process requirements.

The whole crystallisation and evaporation process system evaporates under the vacuum condition, with relatively low temp, fast evaporation crystallisation speed, high evaporation concentration, and the relatively high viscosity of the liquid material is not easy to scale or block, which can achieve the maximum crystal ratio under the same energy consumption.

HongVadar relies on professional design, strict production management, the fine processing procedure, provides high efficiency and energy saving equipment system for the customer. The manufacturing factory has passed the international ISO9001 quality system certification, and with the design and manufacturing capacity of pressure vessels. Customers can choose Chinese GB, International ISO, American standard ASME, European standard PED and other standards for equipment design and production according to their needs.

Continuous Evaporative Crystallization System Technical Parameter

|

Model |

Ev capacity |

Steam consumption kg/h |

Each effect vacuum, mmHg |

Each effect temp. ℃ |

Steam pres. |

Feed DS,% |

Discharge DS, % |

||||

|

1st effect |

2nd effect |

3rd effect |

1st effect |

2nd effect |

3rd effect |

||||||

|

HVD-CC1.0-T |

1000.0 |

330-400 |

300 |

510 |

750 |

85 |

76.0 |

55 |

0.5-0.6 |

5-6 |

55-65 |

|

HVD-CC3.0-T |

3000.0 |

990-1200 |

|||||||||

|

HVD-CC4.5-T |

4500.0 |

1485-1800 |

|||||||||

|

HVD-CC6.0-T |

6000.0 |

1980-2400 |

|||||||||

|

HVD-CC9.0-T |

9000.0 |

2970-3600 |

|||||||||

|

HVD-CC12.0-T |

12000.0 |

3960-4800 |

|||||||||

|

HVD-CC15.0-T |

15000.0 |

4950-6000 |

|||||||||

|

HVD-CC20.0-T |

20000.0 |

6600-8000 |

|||||||||

If you want to know how is crystallization different from evaporation, you can click our official website.

Persona a contactar : Li Danny, +13 8 11 96 92 27

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de Continuous Evaporative Crystallization System Buscar en la categoria : Bienes de equipo Buscar en la categoria : continuous, evaporative, system, crystallization |

Wednesday 05 August 2015

Nos complacemos en ofrecerle nuestra máquina, disponible para venta: * Heidelberg MOVP-S+ - Año 1987 48x65 - 4 colores - CPC 1.01 - Mojado ALCOLOR - Baldwin con refrigeración - Alimentador de hojas Mabeg - Marcador continuo - Control de la delantera y de doble hoja - Sistema de...

ACS DIFFUSION s.a.s.

- acsdiffusionsa

- 42952 - Saint-Etienne

- 0033 (0)4 77 92 77 88

- 06 10 63 37 83

Wednesday 14 September 2016

Cantidad : 5000 - Precio : 50,00 €

Gate Valves (F7 Type) DIN Standard F7 Gate valves / (Length acc.to DIN EN 558-1,face to face series 26 ) DIN F7 Gate valve DIN Absperrschieber F7 DIN Válvulas de compuerta F7 DIN F7 šoupátko stavební délka dle DIN EN558-1 serie 26 DIN Standard F7 sluseventil (lengde iht. DIN EN 558-1...)

ETM Armaturen

- 59590 - Henri Durre

- 86 577 67953935

Tuesday 01 September 2015

Cantidad : 8000 - Precio : 0,50 €

Descripción 1.Nice tacto suave y voluminoso 2. No ver artesa de impresión ambos lados 3 Manténgase al piso después de copiar 4. Sin atasco de papel o doble alimentación 5.Leave hay polvo en la copia de la máquina 6. efecto copia Destacado 7. Material: 100% pulpa de madera virgen...

thongprasertpapers Co Ltd

- 10160 - Bangkok

- +66 9 70 45 08 70