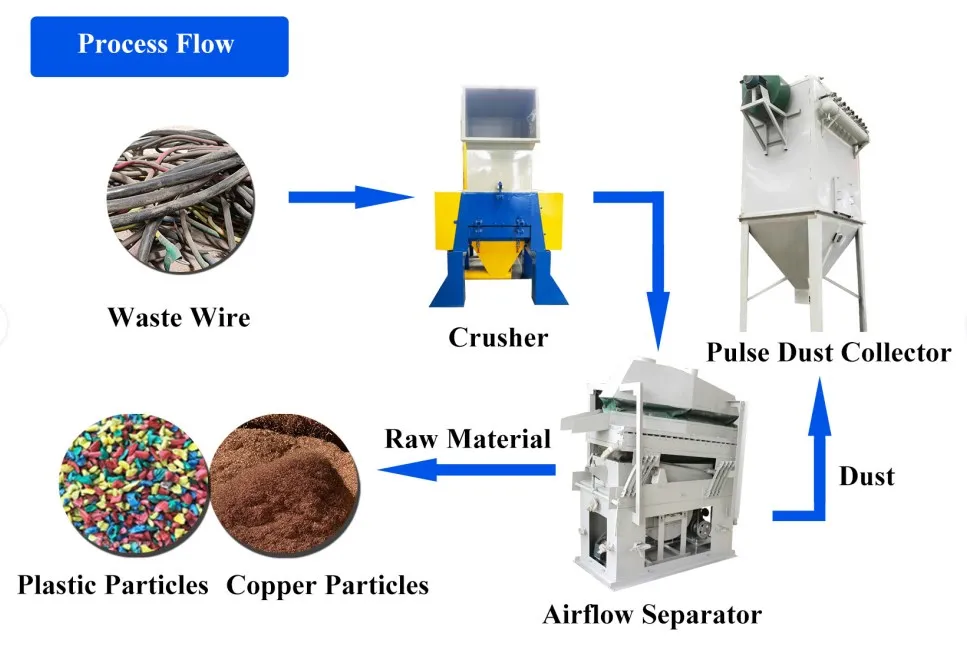

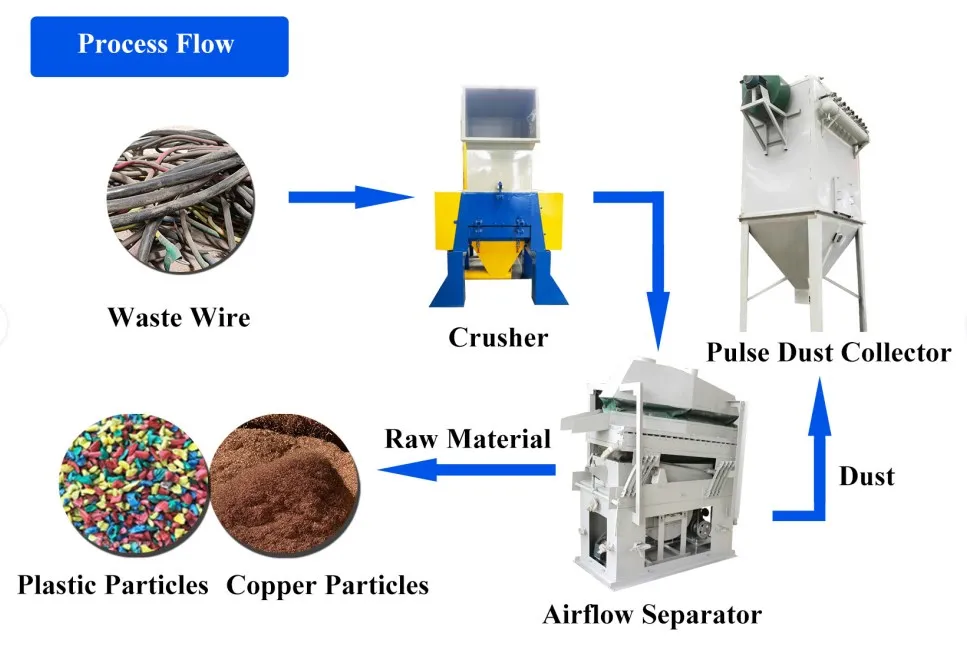

Copper Wire Granulator Cable Recycling Machine Copper Plastic Separation Machine

|

Model

|

Capacity(KG/H)

|

Power(kw)

|

Size(mm)

|

Weight(KG)

|

|

YT-TMJ-200

|

100-200

|

30

|

2400*1800*2800

|

2390

|

|

YT-TMJ-500

|

300-500

|

53

|

6000*6000*4600

|

4790

|

|

YT-TMJ-1000

|

800-1000

|

154

|

20000*12000*4600

|

12000

|

|

Model

|

Capacity(KG/H)

|

Power(kw)

|

Size(mm)

|

Weight(KG)

|

|

YT-TMJ-200

|

100-200

|

30

|

2400*1800*2800

|

2390

|

|

YT-TMJ-500

|

300-500

|

53

|

6000*6000*4600

|

4790

|

|

YT-TMJ-1000

|

800-1000

|

154

|

20000*12000*4600

|

12000

|

Persona a contactar : CUI SHENG, 86 18530843555

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de Copper Wire Granulator Cable Recycling Machine Copper Plastic Separation Machine Buscar en la categoria : B2B Servicios Buscar en la categoria : machine, recycling, copper, granulator, wire, plastic, cable |

Saturday 12 January 2013

Cantidad : 1000 - Precio : 500,00 €

ISO 9001: 2000 Mantra Softech India Pvt. Ltd is prominent biometric fingerprint reader manufacturing organization in India. Company has been operating in biometric security sector for last 8 years in India. Mantra's biometric security solutions accommodates both time attendance solutions...

Mantra Softech India Pvt Ltd

- 380013 - Ahmedabad

- 9998848600

Tuesday 11 August 2015

Precio : 1$ ~30 $

One Lus International is a professional gear shift lock manufacturer in Taiwan and provides a series of gear shift lock to meet customer's needs. The invisible gear shift lock is easy to operate and convenient to use. The invisible gear shift lock is suitable for automatic & manual...

One Lus International Co., Ltd.

- onelusinter

- 833 - Kaohsiung City

- +88 6 77 32 85 66

Monday 07 September 2015

- Feature (click here for details) - - Under the LAN can support more than 10 simultaneous client connections cameras, image lag within 100 milliseconds, supports standard streaming media network protocols, network 8 M per channel bit rate case, no mosaic - The DSP processor...

ZT Technology Group Ltd.

- ellazhan

- 852 - Fo Tan

- +85 2 26 75 75 58