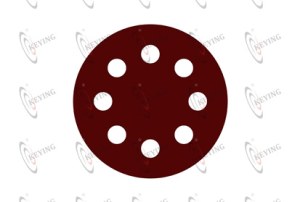

CORSE GRINDING

Coarse Grinding can improve grinding efficiency and reduce abrasive wear. It has the functions of protecting and lubricating the workpiece, deburring, flashing, rounding, removing scale, removing rust and strengthening the metal surface of the workpiece, and leaving a balanced allowance for fine grinding. Make the size of the finely ground stable and better.

Features Of Corse Grinding

Most application of coarse grinding is from heavy stock removal to rough blending, heavy coating, rust removeal, shaping and sharpening , welding treatment, flaws, cracks, risers and painting lines, paint, weld seams removal; edge chamfering and deburring;

It is mainly used to remove burrs, scratches, rust marks, oxide scale, sand holes, bubbles, weld beading, welding and various macro defects on the surface of parts, so as to improve the surface flatness and reduce the surface roughness. The workpiece surface after rough polishing can only reach the level of flatness and smoothness, and can not get a bright surface.

Applications Of Corse Grinding

1

Most application of coarse grinding is from heavy stock removal to rough blending, heavy coating,rust removeal, shaping and sharpening, welding treatment, flaws, cracks, risers and painting lines, paint, weld seams removal; edge chamfering and deburring.

2

It is mainly used to remove burrs, scratches, rust marks, oxide scale, sand holes, bubbles, weld beading, welding and various macro defects on the surface of parts, so as to improve the surface flatness and reduce the surface roughness. The workpiece surface after rough polishing can only reach the level of flatness and smoothness, and can not get a bright surface.

We can offer types of grinding stones for sale, if you have needs to buy grinding stone for stainless steel, please leave us a message.

If you want to know more about how to grind steel, please visit our website.

If you are looking for a reliable abrasives supplier, please contact us, and we will be your best partner.

Keying is always focusing on the manufacture and supply quality advanced abrasive and grinding tools, including various series of abrasive tools, like mounted round flap wheel with shaft, miniature unmounted flap wheels, flap discs, non-woven grinding and polishing wheels/discs, wool felt polishing wheels, mounted points and other abrasive tools.

Persona a contactar : com keyingabrasives, +86(0)576 86711667

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de CORSE GRINDING Buscar en la categoria : B2B Servicios Buscar en la categoria : corse, grinding |

Thursday 16 June 2016

Properties Made of polyester film of 12 microns. Metallic gloss, soft gloss and matte effects, gives the different reflections. “Release resistance” of foils to be sold are “moderate” level. resistance of so-called “moderate” level. In this way, the “silver dust” problem is reduced...

UES Makine Tekstil Inşaat ve Gida San.Tic.Ltd.Şti

- 34510 - Istanbul

- +902125571040

Wednesday 22 April 2015

Cantidad : 1piece - Precio : USD5~36

1 panel solar: 3W Ashiloy Industry co,ltd 2: 3.7V bateria de litio de alta calidad / 4400ma plena capacidad batería. 3.led: Power 3W, 38pcs. Epistar SMD 2835led, temperatura de color 5500-6000k, lumenes sobre 300lm.Brillo equivalente a 12 watts de brillotricolor Lampara de ahorro...

Ashiloy Industry Co.,Ltd

- 999077 - KLN

- +86 138235618632

Wednesday 15 April 2015

Cantidad : Inquiry - Precio : USD 0.8-1.5/piecs

Dimensions : 156mm x 156mm ± 0.5mm. Thickness (Si): 180μm ± 20μm / 200μm ± 20μm. Front : Silver bus bars Silicon nitride anti-reflection coating. Back : Silver bus bars Full-surface aluminum BSF. Ubicación : 5F,No.2.Sec.4.JhongyangRd,TuchengCity.Ta ipei County 236,Taiwan R.O.C...

Taiwan

- 23678 - New Taiwan City

- +886 2 22691686