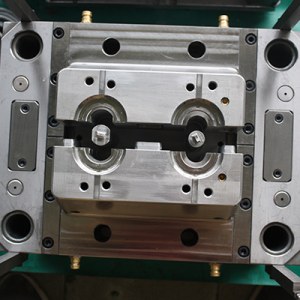

Family Mould

What is the family mold?

A mold that can only produce one product at a time is called a single-cavity injection mold. If a mould is used to produce two or more plastic parts at a time, multi-cavity injection, if the parts are different, such a mold is called family mold.

The plastic parts produced by the single cavity mold have high precision, easy control of process parameters, simple mold structure, low mold manufacturing cost and short cycle time. However, the productivity of plastic molding is low, and the cost of plastic parts is high, which is suitable for large plastic parts, high precision requirements or small batches and trial production.

The plastic parts produced by the multi-cavity mold or family tool injection molding have low precision, it is difficult to control the process parameters, the mold structure is relatively complicated, the mold cost is high, and the cycle time is longer. However, productivity is higher, the cost of plastic parts is lower, and it is suitable for large quantities and long-term production of small-sized plastic parts.

The number of cavities is often determined by factors such as budget, clamping force, plastic part structure, and injection volume.

When designing a multi-cavity mold, one method is to determine the model of the injection molding machine, and then calculate the number of cavities according to the technical parameters of the injection molding machine and the technical requirements of the plastic parts; the other method is based on the requirements for production efficiency and the structure of the part require the number of cavities to be determined, and then choose the proper injection molding machine or check the existing injection molding machine.

We normally make the multi-cavity mold with 2 cavities, 4 cavities, 8 cavities, 16 cavities, 32 cavities, 48 cavities, etc. For family mold, we normally make at 1+1 cavities, 2+2 cavities, 4+4 cavities, 8+8 cavities, we can find the numbers are always double. Family mold help to molding different plastic parts in the same mould, this solution saves tooling and molding cost. For most family mold, the plastic part is in the same material & similar size, HanKing Mould will help customers to analyze the possibility to make the best economic plastic injection mould.

Persona a contactar : Yoyo Tang, 86 13798257041

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de Family Mould Buscar en la categoria : Ropa Buscar en la categoria : mould, family |

Monday 31 December 2012

Cantidad : 10 - Precio : 75 000 EURO

Je vous mets ci-joint la liste des métiers à tisser à vendre : Métiers à vendre : ZAX Tsudakoma, Air-Jet : - 1 ZAX 280 à came, 8 lames, 2 couleurs, année 2000 - 1 ZAX 280 à ratière, 12 lames, 4 couleurs, année 2000 - 1 ZAX 360 à ratière, 12 lames, 4 couleurs, année 1998 - 1...

Friday 08 May 2015

on exploite une mine de plomb au Maroc et on cherche des clients intéressé pour exporter, exploiter le produit du plomb, Zinc…avec la possibilité de fournir une quantité intéressante et un prix imbattable nous vous informons que nous disposons de plusieurs minerais et nous cherchons...

entreprise adil

- casablanca - casablanca

- +212664570629

Friday 14 March 2014

Cantidad : 100000

ARIEL LIQUIDE PROFESSIONNEL REGULAR ET COLOR 65 LAVAGES - 4.55L CONDITIONNEMENT : PALETTE DE 144 BIDONS EN CARTON DE 2 CAMION DE 33 PALETTES PRIX : nous contacter LIVRAISON EUROPE (EN SUS) POSSIBILITE DE PRENDRE UNE PALETTE VOIR CONDITION RENSEIGNEMENT : +33750818561 MIRAGE...

mirage sport

- 66802 - uberherrn

- +4968369217700

- +33 7 50 81 85 61