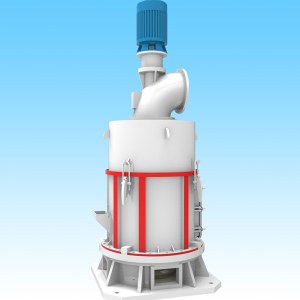

GKW970 Micro Powder Mill

Cantidad : 1 Precio : undetermined

GKW970 Micro Powder Mill is a new modified superfine powder mill developed by our R&D team for grinding 400-1250 mesh powder based on client's need.It is mainly used for grinding non-flammable and non-explosive materials, whose hardness below seven Moh's hardness following humidity below 6%, such as dolomite, calcite, marble, barite, limestone etc. As the top option of grinding 400-1250 mesh powder, CKW micro powder mill is featured with high capacity, wide application, energy-saving, easy operation. Its total installed power is 132KW. If grinding calcite, the capacity is 1.5 t/h for 1250mesh powder.

Technical & Structural Benefits of GKW970 Micro Powder Mill:

1. Finished particle size 400 mesh -1250 mesh (stepless adjustment); 2. Breakthrough hard materials and powdery materials, and grind the materials such as talc and fly ash; 3. Low cost of equipment wearing parts; 4. Convenient equipment maintenance, maintenance & replacement of wearing parts;5. Low energy consumption and high output, for users to create better economic results; 6. Energy conservation and environmental protection.

|

Model |

Max Feeding Size |

Product Fineness (mash) |

Capacity |

Total Installed Power |

|

GKW970 |

≤10mm |

400-1250mesh |

500-3200kg/h |

120kw |

|

GKW1270 |

≤10mm |

400-1250mesh |

1000-6500kg/h |

225k |

Safe Regulations for Operation of GKW970 Micro Powder Mill:

(1) Persons who are familiar with the machine's instruction book and its characteristics are permitted to operate it.(2) Strick shift system is required.It is necessary to have recording book that machine's operation (including running and lubricating the machine, temperature increase at all various parts and seal etc.), output per shift, product quality, voltage, current and the arising fault etc. Should be registered in detail.(3) Starting and stopping must be carried out strictly depending on the regulations in Chapter "Applications".(4) Working place must be kept tidy and clean.No piling is allowed in the powder grinding machine room.After working finished, the machine should be stopped and its surface is wiped clean by each shift.(5) Repairing, refilling and wiping are forbidden while the machine is working.(6) Working with the fault is not allowed.The machine must immediately stop down for maintenance once troubles are found.Re-starting is only allowed after repair.

Persona a contactar : Zeng Ralap , 0773 6812095

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de GKW970 Micro Powder Mill Buscar en la categoria : Construcción Buscar en la categoria : powder, mill, micro, gkw970 |

Friday 25 October 2013

Cantidad : 1000 piece - Precio : USD 0.1 / piece

- Material: neodymium iron boron - Properties: high coercive force, the maximum working temperature is up to 200°C - Grades: N35 to N52, 33M to 48M, 33H to 48H, 30SH to 45SH, 30UH to 38UH and 30EH to 35EH - Shapes and size: disc, block, ring and segment - Coating: Ni, Zn...

Anhui Astromagnet Co., Ltd

- 230011 - Hefei ,Anhui

- 86 0551 63757870

Tuesday 11 August 2015

Precio : 1$ ~30 $

One Lus International is a professional gear shift lock manufacturer in Taiwan and provides a series of gear shift lock to meet customer's needs. The top opening gear shift lock is easy to operate and convenient to use. The top opening gear shift lock is suitable for automatic & manual...

One Lus International Co., Ltd.

- onelusinter

- 833 - Kaohsiung City

- +88 6 77 32 85 66

Tuesday 17 February 2026

Cantidad : 25 tonnes - Precio : A determiner

CUBITAINERS DE GEL DOUCHE + LIQUIDE VAISSELLE + LAVE-LINGE DE TRES GRANDE MARQUE - 15 cubitainers de 1 000 l SOCIETE ATOUT NEGOCE - destockage, valorisation et réemploi des produits. ENTREPOT: 12 - 14 rue Fresnel ZAI PARIWEST 78310 COIGNIERES- MAUREPAS Port: 06.16.59.07.14 Tél: 09...

ATOUT NEGOCE

- lechevrel

- 78310 - COIGNIERES

- 06 16 59 07 14