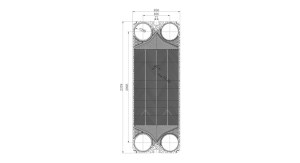

Heat Exchanger Plates

Heat exchanger plates are the key components in plate heat exchangers. These plates are designed with specialized patterns or corrugations to maximize heat transfer efficiency. They provide a large surface area for heat exchange between fluids, ensuring effective and efficient thermal performance in various industrial applications.

Types of Heat Exchanger Plates

Alfalaval Heat Exchanger Plates

Alfa Laval heat transfer plates are specifically designed plates used in Alfa Laval plate heat exchangers. These plates are made of high-quality stainless steel or titanium to ensure durability and corrosion resistance.

APV Heat Exchanger Plates

APV heat exchanger plates are specialized plates utilized in APV (Aurora Plate and Vessel) plate heat exchangers. These plates are meticulously engineered to facilitate efficient heat transfer between fluids.

Tranter Heat Exchanger Plates

Tranter plates feature unique patterns, such as chevron or herringbone, which enhance heat transfer efficiency by creating turbulent flow and maximizing the contact surface area.

Advantages of Heat Exchanger Plates

01

Thin and Flat Components

Heat exchanger plates are thin and flat components typically made of materials like stainless steel, titanium, or nickel alloys. They are arranged in a stacked configuration, with alternating channels for the two fluids involved in the heat exchange process. The plates are sealed together using gaskets or brazing to ensure that the fluids flow through their respective channels without mixing.

02

Specially Designed Patterns

The plates have specially designed patterns, such as corrugations or chevron-shaped patterns, which serve several purposes. First, these patterns increase the effective heat transfer surface area, allowing for efficient thermal exchange. Second, they create turbulence in the fluid flow, disrupting laminar flow and enhancing heat transfer by promoting better mixing and minimizing the formation of boundary layers. This turbulent flow helps maximize heat transfer rates between the fluids.

03

Plate Material

The choice of plate material is crucial in heat exchanger plate design. It depends on the specific application and the properties of the fluids being processed. Different materials offer varying resistance to corrosion, fouling, and high temperatures, ensuring the plates can withstand the operating conditions.

There are many plate heat exchanger suppliers in China, but we are one of the best choices for you.

Persona a contactar : exchange plateheat, 400 088 5662

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de Heat Exchanger Plates Buscar en la categoria : Búsqueda/compra Buscar en la categoria : exchanger, plates, heat |

Wednesday 05 August 2015

Nos complacemos en ofrecerle nuestra máquina, disponible para venta: * Heidelberg MOVP-S+ - Año 1987 48x65 - 4 colores - CPC 1.01 - Mojado ALCOLOR - Baldwin con refrigeración - Alimentador de hojas Mabeg - Marcador continuo - Control de la delantera y de doble hoja - Sistema de...

ACS DIFFUSION s.a.s.

- acsdiffusionsa

- 42952 - Saint-Etienne

- 0033 (0)4 77 92 77 88

- 06 10 63 37 83

Wednesday 07 January 2015

DESTOCKAGE DE MATERIEL DE RESTAURATION PLAQUE A SNACKER ELECTRIQUE. Plaque en acier lisse poli épaisseur 12mm. Themostat réglable de 50° a 300° C . Bac amovible de récupération des graisses . Puissance 3 Kw 230volts nous disposons aussi: plancha avec 2 thermostat: 390 € plancha...

msi trading

- 95240 - cormeille en parisis

- +33 6 62 72 88 46

Tuesday 14 July 2015

Cantidad : 150000/MT

Crema de leche en polvo completa completa Crema de leche en polvo instantáneo, leche entera, leche desnatada en polvo Somos uno de la empresa líder en la exportación aquí en el DE y que la oferta de productos lácteos de alta calidad de todo tipo. Usted encontrará información...

CP FOODS PCL

- 10500 - bangkok

- +66 2 62 61 74 69

- +66 9 62 91 74 71