High Frenquency Welded Steel Pipe Production Line

Cantidad : 6sets Precio : 1000000-6000000

A high frequency pipe welding machine is a system used for manufacturing steel with high-frequency welding technology. The welded pipe production line typically includes equipment such as an uncoiler, accumulator, forming mill, solid-state welder, sizing ERW mill, flying cut-off, and a conveyor system. The ERW pipe mill, ERW tube mill production line is designed to efficiently produce welded steel of various sizes and specifications, ensuring high quality and accuracy. This welded pipe production line technology allows for continuous production, precise control of the welding process, and the ability to produce with excellent dimensional consistency and surface finish. We also provide spiral welded pipe production line for sale. Contact us for more information!

UNDERSTANDING THE BASICS OF HIGH FREQUENCY PIPE WELDING MACHINE

In a high frequency pipe welding machine, the process begins with feeding a continuous strip of steel into an uncoiler. The steel is then passed through a series of rollers and formed into a cylindrical shape in the forming mill. Next, the edges of the steel strip are heated using high-frequency induction to facilitate welding. The heated edges are pressed together and welded using an electric current generated by a solid-state welder. The welded pipe then enters the sizing mill, where it is further shaped and calibrated. Finally, the pipe is cut to the desired length using a flying cut-off machine.

THE IMPORTANCE OF HIGH FREQUENCY WELDING IN STEEL PIPE MANUFACTURING

High-frequency welding plays a crucial role in steel pipe manufacturing for several reasons:

1. Efficiency: High-frequency welding allows for continuous and high-speed production of steel , enabling manufacturers to meet the demands of various industries.

2. Quality control: The precise control of the welding process ensures strong and consistent welds, resulting in high-quality that meet industry standards.

3. Versatility: High-frequency welding can be used to produce of different sizes and thicknesses, making it suitable for a wide range of applications.

4. Cost-effectiveness: Compared to other welding methods, high-frequency welding is a more cost-effective option, as it requires less energy and yields higher production rates.

5. Structural integrity: The high-frequency welding process produces with excellent dimensional accuracy and uniformity, ensuring structural integrity and reliability in demanding applications.

Overall, high-frequency welding is vital in steel pipe manufacturing, delivering efficient production, high quality, and reliable performance in various industries.

KEY FEATURES OF MODERN HIGH FREQUENCY PIPE WELDING MACHINE

Modern high frequency pipe welding machine are equipped with several key features that enhance their efficiency, productivity, and quality:

1. Advanced control systems: These production lines are equipped with advanced control systems that enable precise control of various parameters, such as welding speed, power, and frequency, ensuring consistent and accurate welding.

2. Automated processes: Modern production lines feature automation capabilities, including automatic coil feeding, strip straightening, and pipe cutting, minimizing manual labor and increasing production efficiency.

3. High-speed welding: These production lines can achieve high welding speeds, allowing for increased production rates and faster turnaround times.

4. Quality monitoring: Integrated quality monitoring systems continuously monitor and inspect the welding process, ensuring weld integrity and detecting any potential defects or abnormalities.

5. Material handling systems: Efficient material handling systems, such as uncoilers, accumulators, and conveyor systems, are incorporated into the production lines, facilitating seamless material flow and reducing downtime.

6. Energy-efficient design: These production lines are designed with energy-saving features, optimizing power consumption and reducing operating costs.

7. Quick setup and changeover: Modern production lines have quick setup and changeover capabilities, allowing for easy adjustment between different pipe sizes and specifications.

8. Integration with data management systems: Production lines can integrate with data management systems, enabling real-time monitoring, tracking, and analysis of production metrics for improved productivity and quality control.

These key features collectively make modern high-frequency welded steel pipe production lines highly efficient, flexible, and capable of delivering high-quality that meet industry standards and customer requirements.

As an ERW tube mill manufacturer, we can offer sorts of ERW tube mill machine for sale, if you have needs to buy ERW tube making machine, ERW pipe making machine, please contact us.

Persona a contactar : txhmachine txhmachine, 0317 6213222

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de High Frenquency Welded Steel Pipe Production Line Buscar en la categoria : Bienes de equipo Buscar en la categoria : welded, steel, frenquency, pipe, production, line, high |

Friday 31 October 2014

Model Number: BLB203 New 2200mAh USB Power Bank External Emergency Battery Charger For Mobile Phone 100% New and high quality Small and light fo easy carrying Perfect for business trips, outdoors and traveling Capacity: 2200mAh Input: DC 5V 500mA Output: 5.5V 1000mA weight...

Tuesday 26 January 2016

Round White Rice Type: Rice Texture: Soft Kind: White Rice Variety: Short-Grain Rice Style: Dried Cultivation Type: Common Color: White Broken Ratio (%): 5 % Max. Moisture (%): 12% Admixture (%): 5% Crop Year: new Certification: HACCP, ISO Place of Origin: Ho Chi Minh...

Pacific Production Co., Ltd

- 460000 - Ho Chi Minh

- +84 9 94 85 84 44

Tuesday 23 December 2025

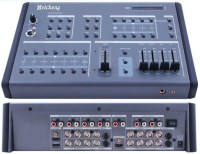

Applications : CMX-12 is a high definition digital AV Mixer, which is a simple type of HD/SD Video Mixer Editor to switch and effects. Each input BUS supports 6 inputs (2 x HDMI, 2 x Component, 2 x S-Video and Composite video) and also Background Color for special effect. The output...

Meicheng Audio Video Co., Ltd.

- meicheng

- 23511 - New Taipei City

- 886 2 82280311