Magnetic Flux Leakage Testing Equipment

Electromagnetic detection is a very important non-destructive testing method and is widely used. Magnetic flux leakage testing is a magnetic method of nondestructive testing that is used to detect corrosion and pitting in steel structures, most commonly pipelines and storage tanks.

The basic magnetic flux leakage principle is that a powerful magnet is used to magnetize the steel. When used in combination with other methods, it provides a quick and inexpensive assessment of the workpiece of ferromagnetic materials. With the advancement of technology, people are paying more and more attention to the automation of the inspection process. This not only reduces the labor intensity of the inspection work but also improves the reliability of the test results and reduces the influence of human factors.

The MFI magnetic flux leakage testing method is a highly automated magnetic flux testing technology. The magnetic flux leakage principle is that after the ferromagnetic material is magnetized, the surface and near-surface defects form a leakage magnetic field on the surface of the material, and defects are detected by detecting the leakage magnetic field. In this sense, the magnetic particle detection technology commonly used in pressure vessel inspection. However, it is customary to use the method of measuring the leakage flux with a sensor as the magnetic flux leakage ndt detection, and the magnetic flux to detect the leakage flux. The method is called magnetic particle detection and they are juxtaposed into two detection methods.

Portable Magnetic Flux Leakage Testing Equipment

Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects on the surface or near surface of the test piece.

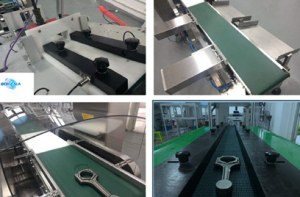

Benchtop Magnetic Flux Leakage Testing Equipment

Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects on the surface or near surface of the test piece.

Magnetic particle testing can only detect surface and near-surface crack defects, and it needs surface grinding when testing. It is only suitable for the detection of workpiece discontinuation. In addition to the surface and near-surface crack defects, the MFI magnetic flux leakage inspection can also find the corrosion inside the workpiece from the outside. Defects such as pits, and do not need to be polished on the surface of the workpiece, suitable for on-line inspection of workpieces. On-line inspection of workpieces is currently the most urgent method for users, which can reduce unnecessary parking and reduce inspection costs. In addition, the magnetic flux leakage detection can also quantify the depth and length of defects. Although the application of magnetic flux leakage detection technology is rarely used in workpiece inspection, it has the advantages that magnetic particle detection does not have, so its application prospect is very broad.

As a non destructive testing equipment manufacturer and supplier, we have been committed to developing and manufacturing high-quality and high-performance NDT equipment to provide customers with the best quality service.

BKN is a professuonal mfl suppliers, we provide ndt testing machine, magnetic flux leakage sensor, ndt testing, etc. Want to know what is magnetic flux leakage or magnetic flux leakage testing procedure? Please contact us.

Persona a contactar : Li Hui, +86 025 52244360

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de Magnetic Flux Leakage Testing Equipment Buscar en la categoria : B2B Servicios Buscar en la categoria : flux, leakage, magnetic, equipment, testing |

Friday 03 April 2015

Precio : compétitif

Conserves de sardines, maquereaux en provenance du Maroc, produits de qualité supérieure a prix intéressant ( seule usine présente a Dakhla, la ou est pechée la sardine donc pas d'acheminement en camion frigo, produits frais) Quantité importantes disponibles à la demande. Produits...

maroc.pelagic

- 80000 - Agadir

- +212668440689

- +212 6 73 62 27 70

Saturday 20 February 2016

Precio : 2000 usd per mt CIF

We sell the best quality White and black pepper.We are selling for the cheapest CIF Prices. We are having free samples for quality testing For pepper, we now supply White and black pepper 500gl/ 550gl/ 570gl and white pepper 630gl Here are the specifications we offer: 1, Product Name...

Khun Jack Partnership Ltd

- 5000 - Chaing Mai

- +66 9 68 75 20 43

Saturday 12 October 2013

Cantidad : 150.000 MT - Precio : CIF $72

We direct facilitators Seller, cement 42.5 R/ N PORTLAND,Caracterist Europe), According to British Standards BS12/96 or ASTM C-150 or DIN , and we can meet your requirement in Algeria, Libya, Africa or ASWP CIF OR CFR - ASWP only work (Safe Harbor) Quantity: Min Quantity 6,250 MT to 60...

cronos promotions & services

- greserver

- 30331 - murcia

- 648039342