Medical Plastic Parts

To be a qualified medical plastic components manufacturer, the most advanced technology and continuous compliance and certification are the pillars of success. Medical progress is advancing by leaps and bounds. We can't imagine how things are now being developed so quickly. It helps improve everyone's quality of life. Our cleanroom facilities are for medical plastic parts and liquid silicone rubber molding. They are all ISO certified to 13485 and 9001. We've been providing the best medical plastic parts production molding solution to BD for over 5 years. Please don't hesitate to contact us for competitive medical plastic solutions like Medical disposables, Medical devices, Medical plastic parts, Medical packaging, and Medical instruments.

Medical Plastic Parts Production Process

As experienced lsr injection molding partner will be value-add compared with price. When injection molders understand and focus on each development stage from mold design and mold flow analysis to process monitoring and quality control, OEMs know that scientific molding will ensure accuracy in processes and production. Therefore, production process control will plays important role in medical plastic parts molding.

Cooperated Engineering Work

A mature injection molding partner is committed to early project participation. The adjustment engineering team provides an opportunity for both parties to agree on which dimensions are process-sensitive and which dimensions can be adjusted through tool modifications. Define and prioritize non-sensitive and tight tolerance dimensions to ensure that time and energy are properly allocated throughout the production process.

Medical Plastic Parts Molding Operation Control

Medical equipment requires separate verification of parameters and settings during the medical plastic parts injection molding process. Molders incorporate this requirement into their processes so they don't confuse these two processes and waste project time on settings that can be adjusted according to equipment requirements, rather than verifying actual parameters (e.g. time, temperature) And pressure).

As the injection molding manufacturers, Packson mold is your strategic partner for meeting your requirements of plastic and silicone rubber injection molding.

Persona a contactar : mould packson, 0086 769 87866635

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de Medical Plastic Parts Buscar en la categoria : Bienes de equipo Buscar en la categoria : parts, medical, plastic |

Monday 24 February 2014

Cantidad : 1 - Precio : 860,00 €

Setter en joyería y los amantes de los bellos motocicletas "Meilleur Ouvrier de France", y creador en el fondo, la realización de la gama alta de las lámparas de inspiración Harley Davidson y engastado con un diamante fuera obvio. Los invito a descubrir mi colección, compuesta exclusivamente...

philippe GOMEZ

- - meximieux

- 06 12 52 01 20

Thursday 08 October 2015

Precio : 900euros

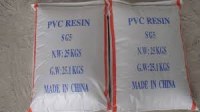

1, une résine PVC 2, Formule moléculaire: (C2H3Cl) n 3, Numéro CAS: 9002-86-2 4, Type: SG3, SG5, SG8 5. Apparence: Poudre blanche ou point blanc, 6. Nombre de viscosité / (ml / g): 114 (ou de la valeur de K) 68-66 ou degré de polymérisation 1135-981 Tuyauterie, plaque transparente dur...

SA BANGKOK IMPORT AND EXPORT LTD

- 10110 - Bangkok

- +66 9 40 61 68 72

Monday 28 December 2015

Cantidad : OEM/ODM Se - Precio : OEM/ODM Services

Soporte de electrodos de grafito es aplicado en horno de grafito de cristal único campo termico. Se utiliza para estabilizar el electrodo de grafito en grafito zona caliente. Electrodo de grafito de Apoyo de hacer el único cristal horno grafito campo termico estructura más razonable...

XRD Graphite Manufacturing Co., Ltd

- zcxooo

- 467400 - Pingdingshan

- 86 15516002510