METAL HEMMING

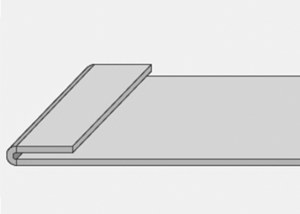

Metal hemming is a process that involves folding the edge of the sheet metal to 180° onto itself. Then, two newly formed layers are flush with each other. Many automotive parts are produced by metal hemming, such as trunk lids, deck lids, hoods, tailgates and doors. There are 4 types of metal hemming: teardrop hem, closed hem, open hem and rolled hem. The closed hem is the most popular one as the process is simple. It is totally flush. However, it has material limitations, including thickness and angle limitations to avoid fracture.

WHAT IS THE PURPOSE OF METAL HEMMING?

Generally, metal forming is used to connect parts together to achieve a better appearance and strengthen the edges of parts.

HOW TO HEM MATERIAL WITH LOW FLEXIBILITY?

For some material such as aluminum, the closed hem is not an ideal choice, since the flexibility them are not enough and they are easy to break during the process. Instead, teardrop hem is the best choice for this material. It is a flange which is bent over more than 180°with only marginal inside radius change, and that is the reason why it can process that low-ductility without fracture.

WHAT IS THE DIFFERENCE BETWEEN METAL HEMMING AND METAL SEAMING?

Hemming and seaming are two very similar metal processing service that both involve bending metal over onto itself. The difference is that seaming is to use a seam to join two layers of metal sheet together and two layers are not flush with each other while on the other hand two layers are flush with each other with hemming.

As one of metalworking suppliers, we will do our best to meet all the needs of customers.

Persona a contactar : com hunkmachining, 0553 2861635

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de METAL HEMMING Buscar en la categoria : Búsqueda/compra Buscar en la categoria : hemming, metal |

Tuesday 17 February 2026

- Ubicación : 111/39/4 Tay Lan Street, Tan Tao ward, Binh Tan district, 700000 Ho Chi Minh, Persona a contactar : Luc Truong, +84 9 86 58 28 62

Qui Phuc Company Limited

- Luck06

- 700000 - Ho Chi Minh

- +84 9 86 58 28 62

Wednesday 14 September 2016

Cantidad : 5000 - Precio : 100,00 €

Bellows Seal Stop Valves (Angle Type) DIN Angle Type Bellows Sealed Stop Valve DIN Bellows Seal Globe Valve DIN Faltenbalgventil Eckform DIN Válvulas de fuelle(Paso angular.) DIN ventil uzavírací s vlnovcem rohový DIN Standard seteventil med belg (Vinkel modell) DIN Standardında...

ETM Armaturen

- 59590 - Henri Durre

- 86 577 67953935

Tuesday 16 February 2016

Cantidad : 5000MT - Precio : 450 USD / MT CIF

Inhibit tumor growth and improve disease resistance; Powerful anti-oxidant which extends life, and improves the memory; Neutralize the side effects of chemotherapy and radiation; Normalize blood pressure & balance blood sugar Lower cholesterol, lose weight. Support eye health...

KHUN JACK PARTNERSHIP LIMITED

- 50000 - CHIANG MAI

- +66 9 56 19 49 81