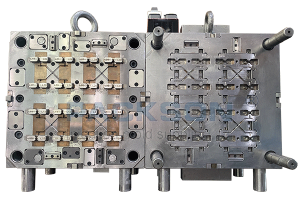

Multi-cavities Injection Molding

Multi cavity mould is an injection mold that has more than one cavity. The shape of each cavity is the same. Multi cavity mold design is to produce multiples of the same part for high volume production since it means each production will produce a large number of finished parts. Multi cavity mold design will help to make high-efficiency production.

Sometimes we will mix up the meaning of multi cavity mould and family injection molds. But these two types of injection mold are totally different. Family injection mold also includes multiple cavities but the shape of cavities is quite different. In other words, family mold is suitable for making different parts by a single run. The family mold can be much harder to maintain during production because of the different shapes of the cavities. It also increases the risk of molding defects.

With the rapid development of mold making, Packson mold also makes the multi cavity mould for meeting the demands of customers. Especially for a medical industry like BD, they have the need for multi cavity mold production. Such as disposable products: injection syringe, testing tube, and container. Feel free to contact us for further details of the multi cavity bait mold solutions today!

Multi Cavity Mould Parameters

|

Cavity Number |

2-120 cavities |

|

Plastic Resin |

PP,PP+20% GF,PA6,PLA,PE,PVC,PS,PC,POM,PET,ABS,TPE/TPR etc |

|

Tooling Material |

P20,NAK80,718H,S316H, etc. 20~60 HRC |

|

Mold Base |

LKM,HASCO,DME standard |

|

Mold Runner |

Cold and Hot Runner |

|

Mold Cold Runner |

Point way, side way, follow the way, direct gateway, etc. |

|

Mold Hot Treatment |

Nitridation, tempering, etc. |

|

Mold Surface |

texture, EDM, high gloss polishing |

|

Mold Cooling System |

water cooling or Beryllium bronze cooling, etc. |

|

Lead Time |

25-60 days |

Why Choose Multi Cavity Mould?

The Benefits of Multi Cavity Injection Molding

A

Multi cavity injection mold can be more than one cavity of the part with the same shape. Multi cavity injection molding is able to produce a large number of parts per molding cycle. It's suitable for high-volume production. Here are some other benefits of multi cavity injection molding:

Quick Lead Time: The cycle time of lead time will be shorter since numerous parts can be done per cycle.

Competitive Mold Cost: The cost of a mold with 2 cavities is cheaper and we will cost less than making 2 separate molds.

Low Part Price: Multi cavity soft plastic mold helps reduce the part price by shorter labor and machine time.

Order Flexibility: It's difficult to meet a demand for a million parts only by mold with a single cavity. Multi cavity moulds enable you to place large production orders that can be accomplished with high efficiency.

A Single Mold VS Multi Cavity Mold

Process For Multi cavity Mould

Packson's quoting system enables us to make quotations quickly by our professional quotation engineer.

Send us your part 3D to get your multi cavity mould and part quote.

Confirm quotation and order issues. Packson starts the multi cavity mold and part order process.

Making DFM and create processing solution.

Tooling design review by Packson engineers.

Get approval of the design. Packson start building your multi cavity mold.

Customer checks samples for approval.

Part mass production begins.

Applications Of Multi Cavity Mould

Packson creates single-cavity and multi cavity moulds for the medical and paramedical industry such as Y-bodies and straight connectors, caps, syringe plungers, syringe barrels, valve components, dispensers nozzles, etc.

From our mold case for medical, we have to build a 4 and 8 multi cavity mould with a full hot runner system also valve gates by rotary index system.

Packson has over 15 years of plastic lsr injection molding experience. Our professional team who is an expert in custom multi cavity injection molding is ready to assist make a custom multi cavity injection molding solution for your application needs.

Persona a contactar : mould packson, 0086 769 87866635

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de Multi-cavities Injection Molding Buscar en la categoria : Bienes de equipo Buscar en la categoria : multi, molding, cavities, injection |

Saturday 20 February 2016

Cantidad : 100 MT PER - Precio : 2000 usd per mt CIF

Hemp seeds Product Name: Hemp seed extract Latin Name: Cannabis sativa L Appearance: Brown yellow powder Part used: Seed Application: Health-care products Shelf Life: 24(month) Name Hemp Seed Botanical source Cannabis sativa L. Specification 3.5mm belwo,3.5-5.0mm...

Khun Jack Partnership Ltd

- 5000 - Chaing Mai

- +66 9 68 75 20 43

Monday 20 July 2015

maroc, vente, plastique recyclée, fournisseurs, distributeurs, importateurs, producteurs , grossistes, import, export. Société italienne spécialisée en production d'un polymère innovant produits parmi le recyclage de polyoléfine et polypropylène cherche importateurs utilisateurs...

impresa in marocco sarl

- 20000 - CASABLANCA

- 06 29 90 85 75

Thursday 16 July 2015

BLANCO REFINADO DE CAÑA DE AZÚCAR ICUMSA 45 ESPECIFICACIONES : APTOS PARA EL CONSUMO HUMANO POLARIZACIÓN : 99,80 % MÍNIMO HUMEDAD : 00,04 % MÁXIMO SULPHATEASH CONTENIDO: 00,04 % MÁXIMO GRANULACIÓN : medio a fino SOLUBILIDAD : 100 % DRY y de flujo libre RADIACIÓN : NORMAL W / O PRESENCIA...

TRADEX GROUP CO LTD

- 15140 - opburi

- +6661409539