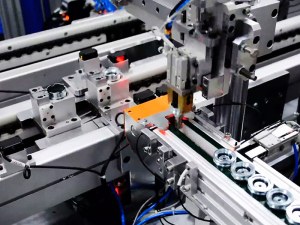

OCV Full-Automatic Assembly Line

Cantidad : More than Precio : More than 300,000

The VVT(OCV)is one of accessories of automotive engine, which was used to control the inlet of engine. VVT(OCV) , electromagnet coil assembly line is a fully automatic line. It is include final assembly station, valve sleeve filter welding station, closing station, air-tightness test and conveyor line. The whole line is consists of many single machine to complete the feeding of each material, press-fitting, data collecting, data output and so on.

Machine feature of OVC Full Automatic Assembly Line

1. Laser welding: After welding, the impurity particles are less than0.2 mm

2. Body closing: Coaxiality of the closing of assembled valve sleeve is less than 0.25mm

3. During welding, the product will not have bruising, scratches and so on.

4. During assembly, many types of detection will be performed to accurately detect the quality of the product, and prevent leakage or wrong loading.

5.Equipped with trace-ability system and poka-yoka solution, it can record and control the data in the process of assembly and detection

Related automation solution:

•Manipulator

•Automatic feeding machine

•Assembly line

•Inspection device

The following is part of the process flow of this machine

1. The assembly of the connector completes the automatic feeding of OCV solenoid valve parts

2. The main line completes the feeding and assembly of parts such as covers and wires, and no bumps or scratches may occur during the assembly.

3. Solenoid valve closing and riveting process, it can monitor the closing pressure value and riveting height

4. Test the air tightness of the product and no bumps or scratches may occur on the valve body during testing. The machine is equipped with functions of error prevention and traceability.

Machine feature of OVC Full Automatic Assembly Line

1. Laser welding: After welding, the impurity particles are less than0.2 mm

2. Body closing: Coaxiality of the closing of assembled valve sleeve is less than 0.25mm

3. During welding, the product will not have bruising, scratches and so on.

4. During assembly, the displacement detection can accurately detect the quality of the product, and prevent leakage or wrong loading.

Machine parameter of OVC Full Automatic Assembly Line

Capacity: FL08.0088.01

Power: AC380V

Floor space: 6360*3900*1800(L*W*H)

Station: 1

Power: 10KW

Dongguan Yiheda Automation Co.,Ltd is one of professional automation equipment suppliers. We provide Automated Assembly Equipment, Automated Test Equipment, automation machine, ovc valve, ovc valves and so on. Want to know about ocv test? Please contact us.

Persona a contactar : Carol Huang, 769 82886777 676

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de OCV Full-Automatic Assembly Line Buscar en la categoria : Varios / Descuento Buscar en la categoria : automatic, line, full, assembly |

Monday 02 March 2026

Palets de devoluciones Action para mayoristas, liquidación profesional y exporta

Cantidad : 30000 - Precio : 0,50 €

Ofrecemos palets de devoluciones compuestos exclusivamente por artículos procedentes de la cadena Action, dirigidos a mayoristas, profesionales del liquidación, revendedores y exportadores. Estos palets de liquidación contienen productos de gran consumo no alimentarios, seleccionados por su alto potencial de reventa y rápida rotación. Detalles de la oferta: - Palets de devoluciones de gran distribución – marca Action - Aprox. 1.000 artículos por palet (80 % de los palets) - Precio medio...

TRANSIDI

- 22440 - PLOUFRAGAN

- 09 72 63 03 26

- 33(0)603670505

Monday 20 August 2012

Cantidad : une machin - Precio : 30000euros

Ubicación : Calle Prado Isidro 45 , 28492 Mataelpino Madrid, Persona a contactar : Allami Azizi cherifa, 639509955

autonomo

- 28492 - Mataelpino Madrid

- 639509955

Friday 03 June 2016

Rassiya S.a.r.l, est une société d'import-export des produits agricoles située à Casablanca, Maroc. Le champ d'activité principale de la société: livraison en gros de légumes frais, fruits, poissons congelés, conserves de poissons, et l'huile d'olives. Nous offrons à nos clients...

Rassiya SARL

- 20000 - Casablanca

- +212 661 49 84 71