Plastic Extruder For Thermoplastic Elastomer

Mixing Modification of Elastomer——Blending Modification of SBS/SEBS

Applications of Thermoplastic Elastomer:

The English acronym of Thermoplastic Elastomer is TPE. In the Chinese market, TPE refers to SBS/SEBS blending modification materials. Because SBS/SEBS elastomer usually has a high viscosity and is difficult to be directly processed, TPE thermoplastic elastomer material (TPS) is prepared by blending SBS/SEBS with plasticizer oil, reinforcing resin, compatibilizer, functional assistant, compatibilizer and so on. Compared with SBS/SEBS, the modified TPE has a lower viscosity, higher plasticity, easier processing and molding. It also has a wide range of adjustable hardness and physical properties. And it does not need vulcanization, can be recycled to reduce costs and other characteristics, so the application field is more extensive. It is mainly used in all kinds of seals, automotive interiors, glue-coated materials, all kinds of pipe fittings, wires and cables, etc.

According to different hardness requirements, SBS or SEBS blending modification adjusts the proportion of SBS/SEBS, PP, filler and filling oil. The increased rigidity of PP, SBS/SEBS and filling oil can improve flexibility.

Features of Thermoplastic Elastomer:

Design of screw barrel with a large aspect ratio. Large aspect ratio L/D=48: 1-52: 1 provides longer residence time, which is beneficial to the melting of resins and elastomers, homogenization and mixing of filling oil and polymers.

High-precision screw and barrel design. The clearance between screw and barrel is small, the dimension accuracy is high, and the screw structure is optimized to effectively complete the mixing process of resin melting, filler dispersion and filling oil homogenization.

Cutting method. At present, the underwater granulation device at home and abroad has been continuously improved, which basically meets the requirements of different hardness, so underwater granulation is adopted.

Mixing modification of elastomer——Description of TPV dynamic vulcanization process

Applications of Thermoplastic vulcanizate:

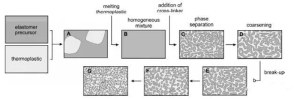

Thermoplastic vulcanizate is referred to as TPV in short. It is a process that combines some properties of vulcanized rubber with processing properties of thermoplastic plastics. At present, the common components are PP, EPDM, filler, filler oil, crosslinking agent and processing aids. The so-called dynamic vulcanization refers to the simultaneous vulcanization (crosslinking) and melts dispersion of rubber. In the continuous phase of the vulcanized rubber phase uniformly dispersed resin, the particle size of the dispersed phase is 1-2 micron under the appropriate temperature field and shear field, which puts forward very high requirements for the blending equipment and preparation technology. TPV products are mainly used in all kinds of seals, soles, , wires and cables.

Features of twin-screw extruder:

The twin screw extrusion machine with high speed and high torsion is adopted. High torque can withstand larger loads and adapt to the characteristics of high strength of vulcanized rubber melt; high screw speed provides a higher shear rate, which disperses vulcanized rubber into small rubber particles and evenly disperses in resin.

Screw barrel with large aspect ratio and multi-way metering feeding. Large aspect ratio L/D=48: 1~52: 1 provides longer residence time, which is conducive to completing the melting homogenization, vulcanization and dispersion of complex mixing process. At the same time, it is equipped with multiple groups of metering feeders to feed resin, rubber, filler, filling oil and crosslinking agent into the barrel step by step.

High-precision screw and barrel design. The clearance between screw and barrel is small, the dimension accuracy is high, and the screw structure is optimized. The melting process of resin and the homogenization process of filling oil is effectively completed, and the dynamic vulcanization process is completed by shearing and dispersing components.

Cutting method. At present, the underwater granulation device at home and abroad has been continuously improved, which basically meets the requirements of different hardness, so underwater granulation is adopted.

The above introduction is a one-step dynamic vulcanization process, which is suitable for the production conditions with a stable formulation ratio. In actual production, due to the different requirements of product performance, the proportion of each component in the formulation varies greatly, and the proportion and degree of vulcanized rubber are also quite different, so the two-step dynamic vulcanization process will have stronger applicability.

Two twin-screw extruder production lines:

The upper twin screw mixes PP, EPDM, filler and a small amount of filling oil evenly and granulates.

The lower-order twin-screw mixes the homogeneous polymer, most of the filling oil and crosslinking agent to complete the crosslinking of EPDM and disperse it evenly.

If you want to know more kinds of thermoset extrusion machines, please visit our website.

There are many extrusion screw manufacturers in China, but we are one of the best choices for you.

Persona a contactar : Chen Eric, +86 25 52705088

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de Plastic Extruder For Thermoplastic Elastomer Buscar en la categoria : B2B Servicios Buscar en la categoria : extruder, plastic, thermoplastic, elastomer |

Wednesday 17 June 2015

Cantidad : 100 - Precio : $3,100.00

- MIMAKI APC-130 Apparel Cutter - 2 Tasks - 1 Machine APC-130 is based on Mimaki's extensive know-how within the cutting market and the company's highly appraised CG-series of cutting machines for the sign industry. Equipped with various functionality required by the apparel and...

PT DIGITAL MEDIA PRINTER

- john michael

- 1440 - Jakarta

- +62 (813) 1183 7053

Saturday 20 February 2016

Cantidad : 1000 MT PE - Precio : 400 usd per mt CIF

Specifications Green mung beans 1.Admixture: Max.0.5% 2.Moisture: Max.14% 3.Imperfect Rate: Max.3% 4.Size: 3.0mm/ 3.4mm,/3.8mm/4.0mm Green Mung Bean Green Mung Bean Moisture Max 14% Admixtur Max 0.5% Imperfect Rate Max 3% Size 3.0mm/3.4mm,3.8mm/4.0mm Place...

Khun Jack Partnership Ltd

- 5000 - Chaing Mai

- +66 9 68 75 20 43

Friday 27 January 2012

We offer you the following high quality products: - Hibernated snails, with expiration period of 12 months, temperature 1 - 6 C° - Blanched, deeply frozen snails with expiration period of 24 months, temperature -18 C°, packed in 0.5kg, 1kg and 2 kg bags. - Snail caviarUbicación : "P...

Bulgarian Snails

- bulgariansnails

- - Varna

- +35 9 52 91 99 28

- +359894679546