Sapphire Substrate Polishing Slurry

Sapphire Substrate Polishing Slurry

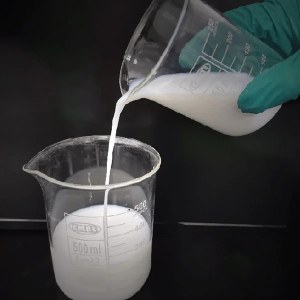

Sapphire wafer is the most widely used substrate material in the semiconductor lighting industry, we developed Silica Colloidal and Alumina Slurry for sapphire substrate polishing.

Kona's Sapphire Substrate Polishing Slurry is designed to meet the demanding requirements of polishing sapphire substrates. Our colloidal silica slurries provide a superior surface finish with no compromise on polishing rates. With high-purity raw materials, our alumina slurries are idealy designed for C-plane sapphire with a fast removal rate and controlled surface finish. The slurry range is available in a wide range of particle sizes to cater to different polishing needs, including fine and rough polishing. Additionally, our Sapphire Substrate Polishing Slurry is compatible with various polishing machines and pads and provides cost-effective solutions for sapphire substrate polishing.

SAPPHIRE SUBSTRATE POLISHING SLURRY FEATURES

Sapphire Substrate is a kind of extremely hard semiconductor substrates, Kona engineering developed Sphere Substrate Polishing Slurry, including colloidal silica and alumina slurry.

In most cases, diamond abrasives is used for sapphire grading. However, which leaves scratches and other strains on the sapphire surface. So sapphire substrates need to be polished use colloidal silica or alumina slurry.

Kona sapphire colloidal silica polishing suspension especially developed for Sapphire, with increased abrasive particle size, which can improve the removal rate as well as no compromise with high quality surface.

Our aluminium rough and final polishing slurry developed for C- Plane Sapphire, with a fast removal rate and controlled surface finish.

DETAILS OF SAPPHIRE SUBSTRATE POLISHING SLURRY

Sapphire substrate is currently the mainstream substrate used for UV LED. Common size of sapphire substrates are 2", 4" and 6". Sapphire substrate has the characteristics of good light transmittance, high temperature resistance, corrosion resistance and high commercialization maturity.

Kona developed silica colloidal for sapphire substrate final polishing, also provides alumina slurry for sapphire substrate rough and final polishing.

|

Pro Name |

Silica colloidal for sapphire |

|

Base Abrasive |

Silica Colloidal |

|

Appearance |

White liquid |

|

PH |

9-12 |

|

Solvent Type |

Water-based |

|

Shelf Life |

12 months |

|

Pro Name |

C-plane sapphire polishing slurry |

|

Base Abrasive |

Alumina |

|

Appearance |

White slurry |

|

PH |

9-14 |

|

Solvent Type |

Water-based |

|

Shelf Life |

12 months |

Persona a contactar : Kona Kona, +18 3 90 90 84 73

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de Sapphire Substrate Polishing Slurry Buscar en la categoria : Varios / Descuento Buscar en la categoria : sapphire, polishing, slurry, substrate |

Friday 16 May 2014

Cantidad : 50000pcs - Precio : $1-25/pc

SLA Y SLS Por qué utilizar estéreo litografía? Estéreo litografía es muy similar a la sls( sinterización selectiva por láser) proceso de prototipado. Es s mejor utilizar sla, cuando acabado superficial y apariencia general directamente desde la máquina es el factor más importante...

Xiamen Karo Co.,Ltd

- karoplastic

- 361002 - Xiamen

- 0086 592 5135406

Friday 16 May 2014

Cantidad : 500000pcs - Precio : $1-25/pc

SLA Y SLS Por qué utilizar estéreo litografía? Estéreo litografía es muy similar a la sls( sinterización selectiva por láser) proceso de prototipado. Es s mejor utilizar sla, cuando acabado superficial y apariencia general directamente desde la máquina es el factor más importante...

Xiamen Karo Co.,Ltd

- karoplastic

- 361002 - Xiamen

- 0086 592 5135406

Friday 16 May 2014

Cantidad : 5000000 - Precio : $0.50-5/pc

Perfil De La Empresa: Totalmente equipado con avanzados cnc maquinaria, tenemos experiencias ricas para precisión fabricación piezas mecanizadas, piezas torneadas, piezas de fresado como por los dibujos para ofrecer la parte superior- muesca productos. Nuestras instalaciones de...

Xiamen Karo Co.,Ltd

- karoplastic

- 361002 - Xiamen

- 0086 592 5135406