Silicon Steel Roller Coating Machine

The roller coating machine of silicon steel annealing coating (SACL) line can be equipped with two main bodies and three stations combined rubber roller coating machine can be configured to achieve rapid non-stop switching of continuous units, so as to meet the needs of various switching and equipment maintenance. It can provide a feeding system to realize automatic solution supply and recovery.

Problems Easy to Occur in Silicon Steel Production

In the production of cold-rolled silicon steel, the coating machine continuously and uniformly coats the surface of the running strip with a certain thickness of the insulating coating. The main body of the coating machine is composed of a frame, a coating roller, a side roller, and a coating liquid collection tank. The upper part of the coil coating machine is equipped with a spraying device for coating liquid.

When working, the coating liquid is sprayed between the upper coating roller and the side roller, and the excess coating liquid flows into the collection tank, and the lower coating roller has a part Submerged in the coating liquid in the collection tank; through the rotation of the upper and lower side rollers and the coating rollers, a certain thickness of the coating liquid is coated on the upper and lower surfaces of the strip steel. Equipped with a coating roller adjustment mechanism, the bearing seat of the coating roller can be adjusted in the vertical direction along the guide rail; at the same time, it is equipped with a side roller adjustment mechanism, and the bearing seat of the side roller can be adjusted in the horizontal direction along the guide rail.

BOYA Solution for Problems in Silicon Steel Production

The existing coating machine is equipped with a pressure sensor on the side roller bearing seat, and the operator can adjust the pressure between the side roller and the coating roller by reading the reading of the pressure sensor, thereby controlling the thickness of the coating. However, the existing solutions have the following problems. First, the pressure sensor must be disassembled every time the side roller is replaced during maintenance, and the pressure sensor must be re-calibrated after every disassembly and assembly, and it is very easy to damage. Second, the pressing force between the upper and lower coating rollers and the strip steel cannot be detected, which is unfavorable to the control of the coating thickness.

As one of roll coater manufacturers, we can offer sorts of roll coater for sale, if you have needs to buy a reverse roll coater , please contact us.If you want to know more kinds of coil processing lines, please visit our website.

Persona a contactar : chinery boyama, 0710 3273725

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de Silicon Steel Roller Coating Machine Buscar en la categoria : Construcción Buscar en la categoria : roller, coating, silicon, steel, machine |

Tuesday 03 March 2026

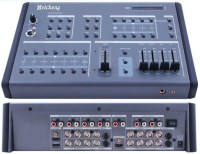

Applications : CMX-12 is a high definition digital AV Mixer, which is a simple type of HD/SD Video Mixer Editor to switch and effects. Each input BUS supports 6 inputs (2 x HDMI, 2 x Component, 2 x S-Video and Composite video) and also Background Color for special effect. The output...

Meicheng Audio Video Co., Ltd.

- meicheng

- 23511 - New Taipei City

- 886 2 82280311

Tuesday 03 March 2026

Tabletop Piston Liquid Filling Machine FP-100 is the best candidate with the consideration of budget. The volumetric piston filler draws liquids and other low viscosity products such as oils or juices directly from a tank or drum It is the simple design, low failure rate and fully...

Autopack Co.,Ltd

- autopacker

- 33454 - Taoyuan City

- +88 6 33 68 98 06

Tuesday 03 March 2026

Cantidad : 80000 Ream - Precio : $0.79/Ream for 8000

ESPECIFICACIONES - Tamaño de hoja: 210mm x 297mm / 297mm x 420mm Normas Internacionales de papel Tamaño (ISO) A4 / A3 - Calidad: Importado 100% pulpa de madera virgen - Blancura: 102-104%, blanco natural - Clasificación: A - Espesor: 106cm - Capacidad: High Speed Copiado 100 ppm...

NATH LAOH LTD

- 50100 - Chiang Mai

- +66 9 95 35 59 56