Silicone rubber for mold making

Cantidad : 200 Kilogr Precio : 5.2-7.4usd/kg

Silicone rubber for mold making applications

Silicone rubber for mold makingis primarily intended for poly resin crafts, PU crafts, PU resin crafts ,gypsum crafts ,unsaturated resin crafts, lighting and candles crafts ,plastic toy , stationery gifts crafts industry, a large statue Buddha, furniture, furniture decorative materials, statues Buddha, artifacts copied, building decoration materials, large-scale cement mold, artificial fossils Factory, Europe component factory, simulation landscapes, animals and plants sculpture, sandstone crafts and so on.

Silicone rubber for mold making features description

Silicone rubber for mold makingis white or red flowing liquid with general hardness of 22-50A°after curing. Molding silicon rubber is a kind elastic silicon rubber mold which features with resistance to deformation, high-temperature, acid-alkali and expansion as well as high reproduction times, good tensile strength, tear strength and elongation.

1 good flowability, light viscosity, easy operation

2 low shrinkage

3 good tension and tear strength

4 no deformation

5 high temperature resistance, acid & alkali resistance and aging resistance

Silicone rubber for mold makingdatasheets

Model: 625# silicone rubber for mold making

Appearance: white

Viscosity (cs): 17000-20000

Hardness (A): 24-26

Tensile strength(kgf/cm2 ) ≥32

Tear strength (kgf /cm): ≥28

Elongation break(%): ≥500

Retractility (%): ≤0.2

Curing agent mixed rate (%): 2-3

Operate time (min): 30

Curing time (hours): 2-4

Model: 628# silicone rubber for mold making

Appearance White

Viscosity (cs)12000~15000

Hardness (Ao) 50~80

Tensile Strength (kgf/c?)=7

Tear Strength (kgf/cm)=3

Shrinkage (%) =0.3

Elongation (%) =200

Mixing ratio (%) 2~3

Operating Time(H) 0.5

Curing Time(H)2~4

Model: 630# silicone rubber for mold making

Appearance: white

Viscosity (cs): 19000-25000

Hardness (A): 28-32

Tensile strength(kgf/cm2 ) ≥35

Tear strength (kgf /cm): ≥30

Elongation break(%): ≥470

Retractility (%): ≤0.2

Curing agent mixed rate (%): 2-3

Operate time (min): 30

Curing time (hours): 2-4

Model: 638#silicone rubber for mold making

Appearance: white

Viscosity (cs): 30000-33000

Hardness (A): 30-32

Tensile strength(kgf/cm2 ) ≥40

Tear strength (kgf /cm): ≥32

Elongation break(%): ≥450

Retractility (%): ≤0.2

Curing agent mixed rate (%): 2-3

Operate time (min): 30

Curing time (hours): 2-4

Silicone rubber for mold making operations

If the customer wants to make large products and large size molds, the mold should be made of silicon rubber with high hardness. On the contrary, if the mold with fine and precision patterns, it should be made of silicon with low hardness. The amount of the curing agent depends on the actual requirements of the customer. If molds requiring fast drying and demolding, more curing agent is needed; contrarily, if molds requiring slower drying and demolding, less curing agent is needed.

(Note: our company does not recommend you to add silicone oil. If a special soft silicone mold or fine detailed and complex patterns products are required, 5%-10% silicone oil can be added to soften the mold for easy demold.)

Frequently asked questions of Silicone rubber for mold making

Why does the silicone rubber mold have few molding times?

The silicone rubber mold has few molding times is due to follwoing reasons: adding too much silicone oil which will destroy the molecular of silicone rubber; making the mold for small and fine detailed products with higher hardness silicone rubber which is easy to break; making the mold for large products with soft silicone rubber which will reduce the tensile and tear strength of the mold, and the mold will have deformation. Thus, we should take the proper silicone rubber to make the mold for suitable products.

Any questions, please feel free to contact Ms Jessica :

FAX: 86-0755-89948030

MOBILE: 86-18938867577

WEBSITE: www(dot)szrl(dot)net

E-MAIL: hysb(at)szr(dot)net

Persona a contactar : jessica xiao, 86 0755 89948294

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de Silicone rubber for mold making Buscar en la categoria : Materias primeras Buscar en la categoria : making, rubber, mold, silicone |

Thursday 27 April 2023

If you want to find a cost effective china 5 axis machining services for your product, YS Rapid can be a good choice for you. Based on our rich experiences and professional expertise, our cooperative china 5 axis cnc machining services are available for both rapid prototyping and small ...

YS RAPID MANUFACTURING LIMITED

- ysrapid

- 518106 - shenzhen

- 8615817251032

Tuesday 01 August 2023

Cantidad : 1 - Precio : 400,00 €

L'huile de pépins de figue de barbarie est extraite des graines du fruit du cactus Opuntia ficus-indica et est particulièrement précieuse en raison de sa richesse en acides gras essentiels, vitamine E et antioxydants. Elle est reconnue pour ses propriétés nourrissantes et hydratantes...

Oriental Group SARL AU

- 40100 - Marrakech

- +212524335449

- +212651925398

- +212600604387

Tuesday 05 March 2024

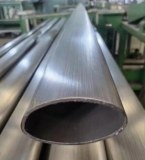

Titanium oval tubing is a hollow metal product made of pure titanium or a titanium alloy that has an oval-shaped cross-section. It is used in various industries, including aerospace, medical, and marine applications, where its excellent properties such as light weight, high strength...

Baoji Yesheng Titanium Industry Co.,LTD

- yesheng

- 721013 - baoji

- 0917 3906666

- +8615289358824