Sintered Neodymium Magnets

Sintered neodymium magnet is the strongest magnetic material commercially available today. It is largely made of alloy of neodymium, iron and boron, and the chemical formula is Nd2Fe14B. Sintered NdFeB neodymium magnet exhibits high magnetic energy product in small size with high coercive forces. Examples of applications include permanent magnet motors, loudspeakers, magnetic separators, wind power generators, computer hard drive, and MRI devices.

For more technical information of our sintered neodymium magnet, please refer to the sections of Technological Advantages, Demagnetization Curve, Grades, Magnetic Properties, Physical Properties, Magnetic Parameters, Surface Treatment, Magnetization Orientations.

Technological Advantages

High Coercive Force

Highest Intrinsic coercive force Hcj≥35kOe

High Consistency

CPK of Remanence (Br) and Intrinsic coercive force (Hcj)>1.67

Low Reversible Temperature Coefficient

αBr=-0.08%/℃, βHcj=-0.4%/℃

Low Weight Loss

130℃, humidity 100%, vapor pressure 2.7bar, 20days, average weight loss<2mg/cm2</span>

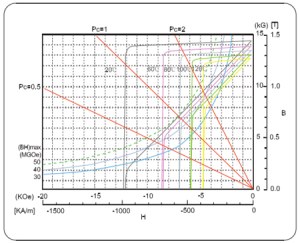

Demagnetization Curves of Sintered Neodymium Magnet

N40UH Demagnetization Curves at Different Temperatures N38EH Demagnetization Curves at Different Temperatures

Grades

The Grade of a magnet generally indicates how "strong" a magnet material is, which is measured by the Maximum Energy Product. The energy product is commonly specified in units of Gauss Oersted. The higher the grade the "stronger" the magnet. The grade also tells the temperature rating of a magnet material. Neodymium magnets have different heat tolerances which determine their maximum working temperature. As the heat tolerance increases the maximum available flux density decreases.

Magnetic Properties of Sintered Neodymium Magnet

Notes:

1. The above-mentioned data of magnetic parameters and physical properties are given at room temperature(20℃±2).

2. The maximum service temperature of magnet is changeable due to the ratio of length and diameter, coating and environmental factors

Physical Properties

Sintered Neodymium Magnets

Magnetic Parameters

Sintered Neodymium Magnets

Surface Treatment

As Neodymium magnet is prone to corrosion, it is usually preferable for the magnet to be coated for protection. Among a variety of options for coatings, nickel and nickel-copper-nickel are the most commonly used, making the magnet more corrosion resistant and durable.

Sintered Neodymium Magnets

Magnetization Orientations

Magnets can be delivered magnetized and un-magnetized. Some production methods require the magnets being incorporated into assemblies in a un-magnetized state and magnetized later once the assembly is completed. There are various magnetic orientations available for different shapes of magnets.

Plates & Blocks

Sintered Neodymium Magnets

Discs & Cylinders

Sintered Neodymium Magnets

Rings & Tubes

Persona a contactar : Tammy Cao, +86 010 53345989

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de Sintered Neodymium Magnets Buscar en la categoria : B2B Servicios Buscar en la categoria : sintered, neodymium, magnets |

Tuesday 20 January 2026

Cantidad : 1 set - Precio : 2000-40000USD

We are manufacturing various pellet mill and complete project, such as high quality fish feed pellet mill, aqua feed pellet machine, shrimp pellet machine, chicken feed pellet machine, cattle feed pellet machine, crab feed pellet mill and so on. Stainless Steel Ring Die Animal...

Changzhou Farthest Machinery Co., Ltd.

- 213332 - Liyang

- 8651983107186

Tuesday 20 January 2026

Cantidad : 1 set - Precio : 2000-40000USD

We are capable of offering feed mill complete project, biomass processing complete project, Compound fertilizer products. Certainly Grinding equipment, Pulverizer, Dosing equipment, Mixing equipment, Pelleting equipment, Extruding equipment, Cooling equipment, Crumbler, Sieving equipment...

Changzhou Farthest Machinery Co., Ltd.

- 213332 - Liyang

- 8651983107186

Tuesday 20 January 2026

Cantidad : 1 set - Precio : 2000-40000USD

We are manufacturing feed mill complete project,biomass processing complete project,Compound fertilizer processing. We can also provide Grinding and Pulverizing; Dosing and Mixing; Pelleting; Extruding and Expanding; Cooling, Crumbling and Sieving; Stabilizing, Drying, Coating and Bagging off...

Changzhou Farthest Machinery Co., Ltd.

- 213332 - Liyang

- 8651983107186