Solar Photovoltaic Support Rolling Machine

SOLAR PHOTOVOLTAIC SUPPORT ROLLING MACHINE

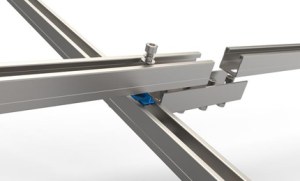

Double-in-roll c-shaped steel photovoltaic bracket is mainly applicable to the ground photovoltaic power station and concrete flat-roof photovoltaic power station. The bracket has a strong adjustable ability, high structural strength, beautiful shape, standard bending angle, accurate hole position, straight angle, accurate size, complete specifications, and economical price, which can meet most of the needs of customers. Double-in-roll c-shaped steel is a special C profile steel. It can also be used for kinds of shelves, ceiling frames, drywall partition, steel structure building, and so on. The series of Hangzhou Roll Forming Technology's solar PV support solar making machine can produce double-in-roll c-shaped steel photovoltaic brackets with consistently high quality at a stable speed.

Features and Advantages of Solar Photovoltaic Support Rolling Machine

Support roll forming for both heavy and light-duty use

Adopt changing spacers to make multi sizes profiles sections

Integrate inline flexible punching system

Pre-cutting and Post cutting is optional

Forming speed around 12-15 m/min

Multi-Patents under both CE Certified, EUROPEAN quality standards

Ready machines in stock for prompt delivery.

Suitable Coil Sheet Material for Solar Panel Rack Forming Machine

Suitable material: Cold/hot Rolled Steel, Galvanized Steel

Thickness: 1.5-3.0(mm)

Yield Strength: 230-300 (MPa)

Width: as profile requests

Technical Parameters of Double Inner Coil C-shaped Steel Photovoltaic Support

|

Installation location |

ground or flat concrete roof |

|

Main material |

hot dip galvanized carbon steel |

|

Design wind pressure |

0.55kN/m ^ 2 |

|

Design snow pressure |

0.5kN/m squared |

|

Service life |

30 years |

Production Line Components and Parameters of Solar Panel Rack Forming Machine

|

1. Decoiler |

3t/5t Motor/hydraulic motor/passive (optional) |

|

2. Feeding table |

|

|

3. Leveling device |

|

|

4. Holes punching device |

as profile requests |

|

5. Roll forming system |

12-15m/min |

|

6. Safety cover |

optional |

|

7. Post cutting device |

|

|

8. Output System |

Manual supporter/ Automatic Stacker (optional) |

|

Stackmaster |

(Output direction) Lateral/Longitudinal (optional) |

|

9. Hydraulic system |

Power supply for holes punching /post-cutting system |

|

10. Electric control system |

MITSUBISH/ SIEMENSE/AMS (optional or as requested ) |

Working Flow of Solar Panel Rack Forming Machine

Pre-cutting flow:

Decoiler (passive/auto) → Feeding and Guiding Table →leveling system → hole punching system (as profile requests) → pre-cutting to length → Roll Forming System → Output Manual Supporter/Auto Stacker(optional)

Post-cutting flow:

Decoiler (passive/auto) → Feeding and Guiding Table →leveling system → hole punching system (as profile requests) → Roll Forming System → Post-Cutting to length (Hydraulic) → Output Manual Supporter/Auto Stacker(optional)

If you need any kinds of tube mill equipment, please contact us, as a professional metal machine manufacturer, RF is willing to offer you high quality products.

Persona a contactar : liu Tyler, +86 571 82686709

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de Solar Photovoltaic Support Rolling Machine Buscar en la categoria : Vehiculos Buscar en la categoria : support, photovoltaic, solar, rolling, machine |

Sunday 17 March 2013

Cantidad : Par Contai - Precio : $ 30.000

Bonjour, On a producteur des ustensiles de cuisine en inox{304, 18chr/10nick} en Turquie depuis 40 ans et nos produits sont haute qualité. On fait specialement d'exportation. on travaille avec plusieurs pays. on produit des casseroles, poeles, marmites, autocuiseurs, cocotte minute...

PREMİER İKRA METAL

- 46010 - kahramanmaras

- 00905436487223

Thursday 29 August 2013

Cantidad : 10 - Precio : 12,95 €

RODILLO DE LIMPIEZA STICKY BUDDY - set completo - PR002101 OFERTA EXCLUSIVA RODILLO DE LIMPIEZA STICKY BUDDY Es el sistema de limpieza perfecto para todas las necesidades del hogar. Sticky Buddy hace desaparecer con una sola pasada el polvo, las pelusas, los restos de comida e...

Fastocks Europe, S.L.

- 46015 - Valencia

- 902099937

Thursday 21 January 2016

Black pepper helps shore up the system with other minerals like potassium for controlling the heart rate and blood pressure, and calcium to strengthen your bones and teeth. 1.Product Name: Black Pepper 500G/L Specification: Moisture : 13.5% max Admixture : 1 % max Density :...

Pacific Production Co., Ltd

- 460000 - Ho Chi Minh

- +84 9 94 85 84 44