URR Cloth Ductwork

Precio : USD0.1-1000

URR™ (UNIFORM AIR VELOCITY, REDUCER, RETENTION)-N SERIES

URR cloth ductwork perfectly integrates uniform air velocity controlling technology with the internal retention ring system. URR cloth air duct system remains round when deflated, absorbing all advantages of both products, It presents more stable inner air velocity, more balanced inner pressure, better visual pleasing effect, easier installation, and higher cost-efficiency.

Advantage

More Stable Inner Air Velocity

Inner Air Velocity on Lengthwise Section

Under the same air supply condition, the internal air velocity curve of ordinary equant round duct is sharply descendant along with lengthwise direction, the air velocity tends to zero at the end cap; UR system can generally ensure stable internal air velocity.

Air Dispersion Direction Diagram of Ordinary Equant Round Duct

Due to vector superposition effect, there is wide difference in internal air velocity from inlet to end cap of ordinary equant round duct.

Air Dispersion Direction Diagram of UR System

Uniform air velocity inside UR system results in same air dispersion direction along the duct.

More Balanced Inner Pressure

Static Pressure Curve of Ordinary Equant Round Duct

Static Pressure Curve of Ordinary Equant Round Duct

Generally speaking, the air velocity is rapidly decreasing inside ordinary equant round duct. Since the static pressure regain leads to the increasing of dynamic pressure whereas less on-way resistance, the overall static pressure from inlet to end cap has a certain increase. PAD must be installed to balance static pressure.

Static Pressure Curve of UR System

Static Pressure Curve of UR System

Since UR system is cone-shaped from inlet to end cap, its on-way resistance is larger than that of ordinary equant round duct. Meanwhile, the internal air velocity is relatively uniform and the static pressure regain is lower. The test result turns out that UR system could basically achieve balanced inner static pressure as long as it is not exceptionally long.

Effectively Slow Down Temperature

Ordinary Equant Round Fabric Duct System

Ordinary Equant Round Fabric Duct System

If ordinary equant duct is running with excessively high surrounding temperature or over-length, the inner air temperature lengthwise has a certain rise.The degree of temperature rise is relevant to duct length and temperature difference between insideand outside duct surface.

UR Air Dispersion System

UR Air Dispersion System

The relatively high axial air velocity of UR system reduces the heating exchange time between the inner air and duct surface, which slows down and reduces the temperature rising. Meanwhile, as the decreasing of surface area along the rear duct results in smaller heating exchange contact area, that is conducive to further slow down and reduce temperature rising. The test result turns out that the temperature rising control efficiency of UR system has been improved for 70% compared with Ordinary equant round fabric duct.

Achieve More Uniform Airflow Distribution

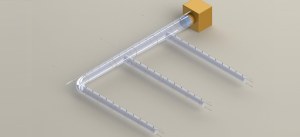

UR System With Multi-Branches

UR System With Multi-Branches

Since the air velocity in main duct of UR system is completely stable and balanced while the included angle between duct surface and branch duct is slightly less than 90°, that is conducive to lead uniform air distribution to each branch.

Ordinary Equant round fabric duct with multi-branches

Ordinary Equant round fabric duct with multi-branches

Different air velocity in main duct of Ordinary equant round fabric duct leads to different airflow supply in each branch, which causes the nearer the branch is to endcap, the more airflow the branch is to receive. ACD is required to balance airflow in each branch.

Advantages of URR Cloth Air Duct

More Stable Inner Air Velocity

More Stable Inner Air Velocity

More Balanced Inner Pressure

More Balanced Inner Pressure

Effectively Slow Down Temperature

Effectively Slow Down Temperature

Achieve More Uniform Airflow Distribution

Achieve More Uniform Airflow Distribution

Inner Air Velocity on Lengthwise Section

Inner Air Velocity on Lengthwise Section

Under the same air supply condition, the internal air velocity curve of ordinary equant round duct is sharply descendant along with lengthwise direction, the air velocity tends to zero at the end cap; UR system can generally ensure stable internal air velocity.

Air Dispersion Direction Diagram of Ordinary Equant Round Duct

Air Dispersion Direction Diagram of Ordinary Equant Round Duct

Due to vector superposition effect, there is wide difference in internal air velocity from inlet to end cap of ordinary equant round duct.

Air Dispersion Direction Diagram of UR System

Air Dispersion Direction Diagram of UR System

Uniform air velocity inside UR system results in same air dispersion direction along the duct.

Static Pressure Curve of Ordinary Equant Round Duct

Static Pressure Curve of Ordinary Equant Round Duct

Generally speaking, the air velocity is rapidly decreasing inside ordinary equant round duct. Since the static pressure regain leads to the increasing of dynamic pressure whereas less on-way resistance, the overall static pressure from inlet to end cap has a certain increase. PAD must be installed to balance static pressure.

Static Pressure Curve of UR System

Static Pressure Curve of UR System

Since UR system is cone-shaped from inlet to end cap, its on-way resistance is larger than that of ordinary equant round duct. Meanwhile, the internal air velocity is relatively uniform and the static pressure regain is lower. The test result turns out that UR system could basically achieve balanced inner static pressure as long as it is not exceptionally long.

Ordinary Equant Round Fabric Duct System

Ordinary Equant Round Fabric Duct System

If ordinary equant duct is running with excessively high surrounding temperature or over-length, the inner air temperature lengthwise has a certain rise.The degree of temperature rise is relevant to duct length and temperature difference between insideand outside duct surface.

UR Air Dispersion System

UR Air Dispersion System

The relatively high axial air velocity of UR system reduces the heating exchange time between the inner air and duct surface, which slows down and reduces the temperature rising. Meanwhile, as the decreasing of surface area along the rear duct results in smaller heating exchange contact area, that is conducive to further slow down and reduce temperature rising. The test result turns out that the temperature rising control efficiency of UR system has been improved for 70% compared with Ordinary equant round fabric duct.

UR System With Multi-Branches

UR System With Multi-Branches

Since the air velocity in main duct of UR system is completely stable and balanced while the included angle between duct surface and branch duct is slightly less than 90°, that is conducive to lead uniform air distribution to each branch.

Ordinary Equant round fabric duct with multi-branches

Ordinary Equant round fabric duct with multi-branches

Different air velocity in main duct of Ordinary equant round fabric duct leads to different airflow supply in each branch, which causes the nearer the branch is to endcap, the more airflow the branch is to receive. ACD is required to balance airflow in each branch.

Where to Use the Cloth Ductwork

Post Air Supply Aress

Post Air Supply Aress

Given high ambient temperature, large airflow and relatively long duct in such areas as machining workshop, URR air dispersion system maintains high and uniform air velocity by continuously changing conicity to achieve even air dispersion and significantly reduce temperature rising.

Large And High-Elevation Facility

Large And High-Elevation Facility

Given large airflow and high ambient temperature in high and large space, UR air dispersion system is applied to obtain higher air velocity at each orifice and long air throw distance with aesthetic appearance.

High Demand For Even Air Dispersion

High Demand For Even Air Dispersion

Given the high requirement of even air dispersion along the duct and strict control of end air velocity, the global leading design software Isox is used to calculate and generate continuously variable diameter UR system to identify as the best uniform velocity air dispersion system.

High Demand For Cost Efficiency

High Demand For Cost Efficiency

Given the high space and large airflow in such areas as logistics warehouse and cold logistics, both effective air dispersion and cost efficiency shall be taken into consideration. UR airdispersion system can not only ensure even air dispersion but also reduce overall cost because of less fabric consumption.

Durkeesox produces cloth duct,we also provide fabric air dispersion and fabric duct design service,yuo can trust us.

Persona a contactar : durkeesox durkeesox, 0086 0711 5919000

Buen trato: comprar del vendedor

Por favor, lea nuestras condiciones de uso. También puede visitar nuestras preguntas frecuentes y ver nuestra información sobre los riesgos relacionados con la falsificación.

|

Esta página es acerca de los importadores y exportadores de URR Cloth Ductwork Buscar en la categoria : Varios / Descuento Buscar en la categoria : cloth, ductwork |

Saturday 08 March 2014

Ideihousse offre de multiples possibilités de personnalisation. Outre la possibilité de choisir différentes tailles de la maison (T0 à T4), les clients peuvent décider de l'aménagement intérieur et les finitions intérieures / extérieures. Dans les murs extérieurs, il est possible...

WinSales

- 3810-183 - Aveiro

- +351 915 650 879

Monday 23 May 2016

Cantidad : 100000 met - Precio : 0.280usd

Thomsun Industries LLC is a professional PPR manufacturers and ppr suppliers in Dubai UAE. T-Mech pressure piping system is considered to be the best carrier of potable water, using the revolutionary raw material of PPR-80 of Borouge brand. T-Mech PPR major products range covers...

Thomsun industries LLC

- Lily Kutty

- 6419 - Dubai

- +97 1 48 85 40 00

- +971551188058

Sunday 08 July 2012

Cantidad : 1 - Precio : negotiated

Mobile diving complex executed in double 20 ft marine containers with 60 m diver depth and diving station for operation of 2 working and 1 standing by divers. 1st container Diving complex: 20' marine container with additional door, illuminators and heat insulation, main switchboard...

MSCO

- 183038 - Murmansk

- +78 1 52 48 10 21

- +79 2 16 66 33 86